![]() September 10, 2021 06:31

September 10, 2021 06:31

A lot of people have moved into the machining industry lately. Especially with the appearance of more affordable CNC machines that allow anyone to craft custom parts right from their garage. However, many still render crudely finished products with sharp edges that make them quite dangerous depending on the intended use. That's where chamfer mills come into play.

It is common courtesy to chamfer any sharp edges off your parts or finished products to prevent accidents. Having a piece of furniture or piece that catches on clothes or causes some slashing damage can be grounds for serious problems.

Of course, you can create smooth surfaces by just filing your edges at a 45 degrees angle, or use a grinding disk. But when you´re machining, precision and accuracy are essential.

Chamfer mills provide both precision and speed. They not only take care of rough edges but also leave a much better finish. Additionally, they easily reach difficult angles without a problem and do a great job at smoothing out punched holes and prepping them up for threading.

Now, imagine we not only have to smooth out the surface, but we also need to modify the angle at which two surfaces meet. Carbide chamfer mills help you remove all those nasty 90 degrees edges and corners, creating a better-looking beveled slope while removing burrs along the piece.

This is also useful when preparing a piece for welding as chamfering provides a smooth surface to allow for a much stronger weld, and reduces the need for clearing excess material when finished.

A chamfer mill can also be used for finishing purposes. Carbide cutting tools have very sharp edges that easily remove material, leaving a perfectly polished surface that saves you time by eliminating the need of buffing out imperfections. I have found that machining and chamfering with carbide cutting tools make it easier to get parts that are ready for service right off the bat. Just make sure your bit engages the material correctly when machining tough alloys. A sharp edge can eat through your carbide and chip the tool easily if you´re not careful enough.

You can also use chamfer mills for engraving or creating channels along the surface without having to go through the finishing process. Carbide chamfer mills keep heat under control, allowing the drill to go through a lot of material without the risk of warp or chatter, leaving perfectly polished floors and walls.

So, even when your CNC or machining operations require minimum finishing, smoothing out edges and offering a polished surface is always a plus when delivering metal parts. We recommend having a few carbide chamfer mill bits in your arsenal. However, make sure they´re made here in the US from a manufacturer with great reviews. Our favorite is www-onlinecarbide.com as they offer incredible wear resistance and a great variety of tools for machining both soft and hard alloys. Their sales representatives are top of the line and provide advice on the right bits or angles for your machining projects.

Posted September 10, 2021 06:31

![]() September 6, 2021 09:08

September 6, 2021 09:08

Threads are an essential part of all sorts of components and connectors. From the pipes that feed water into our homes to the machines that make building those homes possible, threaded surfaces literally hold everything together. The process of cutting threads has taken many different forms over the years. Thanks to the popularity of CNC milling machines in the area of manufacturing, thread milling has become a popular way to add threaded surfaces to pipes and custom made components. If you want to thread mill efficiently it is important to know when to use single pitch thread mills.

Traditional thread making tools like taps and dies can have their drawbacks. They can take time and often require tool changes to produce threaded surfaces of different diameters and pitches. When chips fail to evacuate from these tools they can also cause some serious jams, potentially damaging the workpiece or the tool itself. Thread milling tools can tackle the same tasks in seconds with significantly less risk of the tool jamming or causing issues during the cut.

Some of the most common thread milling tools are known as full form tools. While these cutters are extremely fast and efficient, they are not always the best fit for a job. These thread cutting end mills have rows of sharp cutting teeth that are spaced to correspond to the desired thread pitch. When making a cut, the tool moves in a 360 degree angle while dropping the length of a thread pitch in order to form a uniform helical thread.

While this process allows threads to be cut in a second or less, it's still not always the best choice. Every full form tool can only cut threads with a uniform pitch, though they can be used to cut internal or external threads that are either left or right handed. These tools should only be used on very stable workpieces because they have a large cutting surface. If you have to deal with mixed thread sizes or unstable worpieces, then single pitch thread mills might be the best tools for the job.

Single pitch thread mills are designed with only a single cutting point instead of the full row of points found on a full form thread mill. This means that the tool has to trace along the entire threaded surface, which will take longer than using a full form tool. While the process might take a little longer, a single tool can create threads with a wide range of different pitch sizes, making them a great option. They can also be used to thread delicate surfaces like thin walled components and overhangs with ease.

If you are looking for some single pitch thread mills for your shop, then Online Carbide is the brand to check out. Their US made thread mills are second to none and are ground from high quality tool carbide stock. You can see their thread mills and all of their other cutting tools when you visit www.onlinecarbide.com.

Posted September 6, 2021 09:08

![]() September 3, 2021 06:02

September 3, 2021 06:02

When it comes to accuracy, milling machines are truly amazing tools. They are capable of performing extremely complex operations very quickly to shockingly tight margins of error. Sadly certain longer cutting tools like drill bits are not always the most accurate when using these machines. Luckily using spot drills to your machining process can significantly improve how accurate your longer twist bits can be.

So what is the issue with drill bits? Simply put, the issue is tool vibration. All high speed tools oscillate slightly due to the centrifugal forces they are encountering. When the tool is long relative to their width like a drill bit, this effect can be a little more pronounced. This can lead to the tool having enough of an oscillation that the point of the bit will be swinging around the center of the bit's rotation.

When a bit that is oscillating contacts a hard surface, it can deflect instead of penetrating as intended. This can even cause the drill bit to walk off its mark entirely. Obviously this is a big issue, especially when accuracy is crucial on your workpiece. One of the best ways to improve your accuracy is to create a surface that will provide your drill bit with an easier location to drill. This can be achieved through spotting.

Spotting is the process of creating small dimples on the surface of a workpiece to mark the location of future holes. The process is almost like countersinking for a hole that does not exist yet. The best tool for spotting is a spot drill. Unlike your average drill bit, a spot drill is not designed to drill deep holes. Instead, they are limited to a fluted point that is made to cut cone shaped dimples into your workpiece. These tools are short by design, which makes them extremely stable. Carbide drills are a great option because carbide's structure is more rigid and tolerant of heat than other tool materials like high speed steel.

The process of spotting is usually quick and easy, all you need to do is make sure the spot drill has a point angle that is larger than or equal to the point angle of your longer twist drill bit. As long as this is the case, you can drill all of your spots so that your longer twist bits will hit their marks perfectly. It's also important to make sure that you are using a proper spotting drill and not a center drill or similar looking tool that often may have a smaller point angle.

If you need high quality spot drills for your shop, then you can find some high performance solid carbide options when you visit www.onlinecarbide.com. All of Online Carbide's tools are manufactured in America using high quality carbide stock. If you have any questions about any of the tools that they offer, feel free to reach out to a member of their team by sending an email to sales@onlinecarbide.com.

Posted September 3, 2021 06:02

![]() August 30, 2021 05:58

August 30, 2021 05:58

If you are not already using TiAlN coated end mills, you might want to make the switch. End mills and other milling cutters have to tolerate extreme forces and temperatures, which can shorten their tool life. If you are not using coated tools, then you might not be getting the most out of your cutters.

End Mill Fatigue

All high speed tools have to deal with fatigue. The strain caused by friction at high speeds is immense and can even damage your tools. This is particularly true with end mills made from steel alloys due to the fact that their hardness is directly related to the temperature at which they are tempered. If the heat from friction rises above the tempering point, the structure of the metal can realign into a pattern that is not as hard, limiting the effectiveness of its edges.

One way to avoid this is to use tools made from carbide, which get their cutting power from grains of carbide ceramic embedded in the tool stock instead of from heat tempering. Despite being more resistant to heat and lasting longer than steel tools, carbide tools will still fatigue over time. One of the best ways to extend the life of any milling cutter is to coat it in a material like TiAlN.

Titanium Aluminum Nitride

Known by its chemical shorthand TiAlN, titanium aluminum nitride is a special metastable tool coating. TiAlN coated end mills are capable of deflecting heat away from the body of the cutter and into the chips. One of the biggest benefits of TiAlN is the fact that it has a low coefficient of friction, which helps to limit wear resistance and less heat is generated. When heated, TiAlN produces a layer of aluminum oxide that helps to provide extra insulation during high heat applications.

Physical Vapor Deposition

Now when you think of a tool coating, you might worry that the thickness of the coating material could interfere with the sharpness of the tool's edge. This would certainly be the case if we were talking about a coating that was crudely applied like paint, but tool coatings are deposited using physical vapor deposition. There are several techniques that are used but all involve placing the tools into a vacuum, vaporizing the coating material, and then having it resolidify on the tool surface. The major advantage of this is that a stable coating that is a fraction of a millimeter is achieved. Because the process takes place in a vacuum, the coating bonds directly to the body of the tool and offers incredible protection.

If you are interested in having tools that can run faster and last longer, then the TiAlN coated end mills available from Online Carbide are the perfect option. These tools are precision ground in the Us from high quality carbide and treated with titanium aluminum nitride TiAlN coating to offer a smooth surface finish that can withstand high temperatures. All of their tools are available at manufacturer direct prices when you visit their online store at www.onlinecarbide.com.

Posted August 30, 2021 05:58

![]() August 27, 2021 02:20

August 27, 2021 02:20

Milling machines are amazing pieces of machinery for several reasons. Using specialized cutting tools, a computer guided milling machine can perform extremely complex jobs in a fraction of the time that it would take using other machines. One of the downsides to operating at high speeds is the fact that it can often lead to extremely loud tool chatter. The best way to cut down on chatter without slowing down production is to switch to variable end mills.

Tool chatter is a noise caused by the vibrations of your cutting tools. The effects of chatter can vary dramatically depending on the materials being cut, the end mill being used, and the speed and feed rates being used. All tools vibrate at high speeds because even very solid feeling materials like metals are actually flexible. To imagine the issue at hand, picture what would happen if you spin a length of rope between your hands. The rope with flex and bow outward and the exact same thing happens with your cutting tools, albeit to a lesser degree.

The tool paths being used by your machine cannot perfectly account for this effect. This means that your tools are swinging into and impacting the workpiece constantly, occasionally putting a large amount of strain on both the tool and the edge of the workpiece. Because these tiny impacts are occurring a fraction of a second apart, the sound that they make combines into a high pitch screeching sound.

Operating at lower speeds can help to reduce tool chatter, but it will also cost you time. If you want to maintain a fast paced production without having to deal with the ear splitting noise, then using a variable end mill might be the perfect solution. The idea of these tools is that they are designed to be slightly asymmetrical. This leads to the impact forces between cuts being slightly different.

So what is the advantage of asymmetry in your end mills? It's easiest to explain by imagining the process of dribbling a basketball. When you dribble a ball, you apply the same force every time the ball reaches your hand, which leads to a stable rhythm. That is the same thing that happens to your tools. When the impact force is uniform and the timing is evening spaced, the tool builds an internal oscillation that amplifies the vibrations. Variable end mills apply uneven forces, which makes it harder for the tool to reach a consistent rhythm. By breaking up those regular internal forces, you can reduce chatter and harmonics.

If you are tired of dealing with tool chatter, then adding some variable end mills to your arsenal is the perfect way to keep the volume down without slowing down production. You can find high performance variable helix end mills when you visit www.onlinecarbide.com. All of Online Carbide's tools are manufactured in the US from high quality solid carbide stock and are available at manufacturer direct prices. Pay them a visit if you are looking to save big on the tools that your shop needs.

Posted August 27, 2021 02:20

![]() August 13, 2021 03:22

August 13, 2021 03:22

Spot drills and center drills are part of any drilling and machining operation. One of the most important aspects of machining parts is to drive holes with laser precision accuracy. You know that a hole that is off by a tenth of a millimeter can render a part useless, and there are no “undo” hotkeys in this business.

The problem is that twist drills or “jobbers” tend to “walk-off” when they first come in contact with a surface, especially when milling hard metal and alloys, no matter how tightly secured they are to the spindle. This happens because they are usually longer and more flexible than stub and spot drills.

Center Drills

Now, many CNC enthusiasts like using center drills for spotting since they are usually cheaper, and easier to find. However, the intended function of a center drill is to create a hole that helps secure a part in a lathe.

I can see why it might be the first pick for many when they understand the importance of spotting, as the pilot tip might suggest that it is its main purpose. However, if your operation requires a lot of spotting, the brittle center drill tip will not last too long.

There is one other problem: the countersink. When you're spotting, you want a hole angle that is equal to or greater than the twist drill angle. If the opening is too narrow, the recently drilled dimple will be a death trap for your bits, especially if they´re carbide-coated.

Now, it does not mean that center drills are not good for spotting. They do a good job as long as you only use the tip of the pilot, and don't abuse the tool. As we said before, the tip is very brittle and can only take you so far.

Spot Drills

True spot drills are the perfect tool for the job. They are chubby and rigid and generally provide the perfect anchorage for your jobber. The chunky shank helps to keep the tip right on target, providing maximum accuracy, and preventing it from walking off.

Some might say that spot drills are not necessary, or even detrimental if you´re using carbide drills. However, longer drill bits with carbide-coated tips are still too flexible and will deflect off or even start a hole at the wrong angle.

So, what's the solution?

Just remember that the tip angle of your twist drill must at least match that of your spot drill. That is the best way to protect your sharp carbide edges to come in contact with tapered angles that can damage your carbide tips. A matching point angle will help your tool find purchase quickly and engage the material right off the bat.

There seem to be very few trustworthy spotting drill bit suppliers. If you want excellent customer service and really durable tools, visit www.onlinecarbide.com. They manufacture all of their carbide bits and have plenty of spot drills to choose from.

Posted August 13, 2021 03:22

![]() March 22, 2021 04:27

March 22, 2021 04:27

Spot drills are compact tools that are easy to overlook, but they serve an important purpose in any machine shop. These little cutting tools are important for drilling holes with extreme accuracy, a task that can be difficult when milling.

What makes drilling such a risky procedure when it comes to milling is the potential for drill bits to deflect off of hard surfaces. Drill bits are relatively long compared to other milling cutters and that length comes with drawbacks. Long tools, especially those constructed from steel alloys like high speed steel, will naturally wobble while they spin. This can lead to them not hitting the surface of a workpiece at the optimal angle, which can deflect the point of the drill bit and ruin the cut.

Because milling is typically a very precise machining process, this can cause some serious problems. End mills and other cutting tools are more stable because of their width to length ratio, meaning this problem is almost only isolated to jobber length drill bits with a long flute length. Using carbide drill bits can help to minimize this issue due to their increased rigidity, but spot drills are another great way to produce accurate results.

Spot drills are short drill bits that usually just have a drill point and little to no flutes beyond that point. Their extremely short length makes them far more stable than longer twist bits. Instead of being designed to drill holes, these tools are intended to begin drilling to create a cone shaped dimple on the surface of a workpiece.

This depression helps to mark the location of hole you want to drill with your longer twist bit. Instead of deflecting off the surface, the point of your longer bit will be guided into the dimple created by your spot drill. The spotting process will greatly increase the accuracy of your holes.

In order to get the best results while spotting you need to consider a few things about your tools. If the point angle of your spot drill is not equal to or greater than that of your longer bit, you can still risk the bit deflecting on contact. This is a common issue when operators use a center drill in place of a spot drill. You should also consider your tool materials. You should spot drill when using steel drill bits but spotting may not be necessary when drill with carbide bits, especially of shorter lengths.

If you need some spot drills or some carbide drill bits for your milling machine, you should check out Online Carbide. They are an American manufacturer of high performance solid carbide cutting tools. When you visit www.onlinecarbide.com you will find manufacturer direct prices on products like jobber drills, stub drills, spot drills, drill mills, and several types of end mills. You can also reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com if you have any questions about their tools.

Posted March 22, 2021 04:27

![]() March 3, 2021 05:58

March 3, 2021 05:58

While drilling holes is a common carpentry task that can often be achieved quickly and easily, things become a little more complicated when it comes to milling harder materials like cast iron and steel. When used for these tougher jobs, drill bits have a tendency to deflect off of hard materials and miss their marks. This is what makes the use of spot drills so important, especially when you are drilling into hard materials at high speeds.

Drill Bit Length

One of the biggest factors that leads to issues with drilling operations is the length of the drill bit being used. The longer the tool, the more of a wobble it will have at high speeds. All tools oscillate somewhat when they rotate, though these vibrations are usually too small for us to see with the naked eye. These small vibrations can have big repercussions, because the bit will have a harder time finding purchase in the desired center point. Using shorter drill bits can alleviate this problem, but there is no guarantee that a shorter drill bit won’t deflect.

Spotting

The best way to produce accurate results when drilling into a hard surface is to spot the drill site ahead of time. Spot drills have drill bits that have a very small cutting surface. Typically just the point of the cutter is fluted to make cuts. Instead of being designed to drill holes like other drill bits, these tools are designed to perform a process known as spotting. Spotting is the use of spot drills to create small dimples on the surface of a workpiece to mark the location of holes. Because these tools are so short, they can produce extremely accurate spot points. These points will later help longer twist bits create holes with significantly lower risk of deflecting off the surface of a workpiece.

Choosing the Right Spot Drill

Spotting is a simple process that can offer incredible results, but there are a few important considerations to make sure that your drilling will go as smoothly as possible. Even if a hole location has been properly spotted, the tip of your longer drill bit can contact the side of the spotted location instead of seating properly in the bottom of the spotted point. In order to achieve this, the point angle of your spot drill should be greater than or equal to the point angle of your final drill bit.

If you have been having trouble producing accurate holes while milling, then adding spot drills to your routine could be a great way to get the results that you are looking for. You can find a wide range of high quality drill bits and end mills when you visit www.onlinecarbide.com. Online Carbide is an American tool manufacturer that makes all of their tools from sturdy tungsten carbide tool stock. If you have any questions about any of the tools they carry, feel free to reach out to a member of their team by sending an email to sales@onlinecarbide.com.

Posted March 3, 2021 05:58

![]() February 22, 2021 01:08

February 22, 2021 01:08

Drilling into hard materials like cast iron and steel pose a few risks. Drill bits are long and flexible tools, which can make them difficult to position accurately. This is especially true when drilling at high speeds. Even while using a milling machine to precisely align the cutting tool, drill bits still have a tendency to “walk off” their mark when they come in contact with hard surfaces. If the accuracy of your holes is important on your workpiece, then using spot drills is the best way to ensure proper placement.

What is a Spot Drill?

When most people imagine a drill bit, they are thinking of a jobber length bit. These tools are long and feature long twisted flutes, terminating in a pointed cutting tip. By contrast, spot drills are extremely short tools that only feature a pointed tip and minimal fluting. Instead of being designed to drill deep holes, these drill bits are only designed to create a small dimple on the surface of your workpiece. This is a process known as spotting.

How Does Spotting Help?

The idea of spotting is not to drill a hole, but rather to mark the location of where holes need to be drilled with a longer twist bit. This means that when the larger bit is used, it’s point will find solid purchase within the spotted dimple instead of deflecting off the surface. This will lead to producing extremely accurate results with much less of a risk to your workpiece.

Choosing a Spot Drill

There are a few considerations to make when choosing which spot drill to use. The best options will be made of solid carbide, as carbide is more rigid than steel. This means that the spotting process itself will be more accurate when using a carbide drill. In addition you need to consider the point angle of your spot drill compared to the point angle of your longer twist bit. If the angle of the spot drill is smaller than the angle of the longer bit, then the bit can catch along the edge of the dimple produced during spotting. This is one reason why it’s important to use a real spot drill instead of a similar tool like a center drill, which tend to have smaller point angles.

If you need to produce extremely accurate holes using your milling machine, then spotting is the best way to ensure success. You can find some high quality spot drills, drill bits, and end mills for your milling machine when you visit Online Carbide. As an American tool manufacturer, their team is dedicated to making high performance tools from solid carbide tool stock. Their spotting drills are available in a polished carbide finish or TiAlN coated and are available with 90 degree or 120 degree point angles. If you have any questions about their carbide drills and end mills, you can send an email to sales@onlinecarbide.com to talk to one of their machining experts.

Posted February 22, 2021 01:08

![]() November 30, 2020 00:48

November 30, 2020 00:48

When it comes to drilling holes, the process can be simple or complex depending on the level of accuracy that is required. If you are just doing something simple like drilling a pilot hole into wood, you can usually just go for it and produce results that are clean and accurate. If you are using a milling machine to place a hole in a piece of steel or other hard material, you will need to use a few tools to get the job done right. Spot drills and carbide twist bits are the best way to make sure that your holes are drilled exactly where you need them everytime.

Drill Bit Issues

Your average drill bit is a long tool with a pretty large cutting surface. Sadly tool length tends to have a negative impact on the accuracy of that tool. Virtually all materials have some level of flexibility, including metal. This means that when rotating at high speeds, your drill bits will begin to flex. You might not be able to see this phenomenon with the naked eye, but the tip of your drill bit will wobble slightly around its central axis. This leads to drill bits deflecting off of hard surfaces and “walking” off their mark, potentially damaging your bit and your workpiece.

Spotting

One way to significantly increase the accuracy of your drill bits is to spot the hole before drilling it. The process of spotting involves using a much shorter and more accurate tool to create a dimple in your workpiece that your drill bit can fit into cleanly. Spot drills are short tools ending in a sharp pleated point and are only designed to penetrate the workpiece for the length of the cutting point. Carbide spot drills are extremely rigid, making them one of the best options when accuracy is important.

Final Drilling

As long as you have properly spotted the hole, you should be able to drill it nice and easily. The most important thing to consider is the drill point angles of your spot drill and your final twist carbide drill bit. As long as the spot drill has a wider angle, the twist bit should be able to reach the base of the spot drill’s depression without contacting one of the edges first. This will help ensure that the final hole is clean and centered.

If you are looking for spot drills and carbide drill bits for your shop, you need to try the solid carbide tools from Online Carbide. The team at Online Carbide are dedicated to producing high quality end mills and drill bits from solid micrograin tungsten carbide. All of their tools are made to precise tolerances using extremely accurate computer guided grinding machines, meaning their end mills and drills are designed with sharp and accurate edges from day one. If you have any questions about their products or you are interested in ordering custom cutting tools for your shop, feel free to reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted November 30, 2020 00:48

![]() October 12, 2020 02:37

October 12, 2020 02:37

There are many different types of drill bits and drill like tools. Sometimes it can be a real challenge trying to tell them all apart. Two of the most commonly mixed up drills are spot drills and center drills. While these tools may look somewhat similar and seem to be interchangeable for certain applications, they have a few key differences that are important to note.

Spot Drills

Spot drills are short tools with a small pointed cutting surface. As their name suggests, these tools are primarily used to “spot” the location where a twist drill bit will be used. On hard surfaces like steel and other metals, drill bits have a tendency to deflect and “walk” off their mark. This can damage both your workpiece and your drill bit.

The point of a spot drill is to create a small dimple that a longer twist bit can easily fit into. This helps to ensure that your bit will find its mark without issue. The biggest consideration when choosing a spot drill is to ensure that the point angle of your spot drill is greater than the point angle of the longer twist bit being used. This will ensure that the bit contacts the bottom of the spotted divot instead of deflecting off its side.

Center Drills

Center drills are another short tool designed with a small point cutting surface. Unlike spot drills, center drills feature a central extension to their point. This small protrusion serves as a pilot drill while the rest of the cutting surface acts as a countersink to widen that pilot hole. These tools are designed to mark the center point of material so it can be prepared to be lathed.

Some machine operators will use a center drill in place of a spot drill. While these tools are certainly capable of creating a dimple in a workpiece, there are a few important differences in design that make them ill suited for spotting. Center drills typically have a more narrow point angle than spot drills, which makes them particularly ill suited for spotting. If you do spot with a center drill, you run the risk of your drill bit deflecting off of the edge of the divot created in your workpiece.

Both of these tools are important for machinists, but they are definitely not always interchangeable. Using the wrong milling cutter for a specific application can have devastating effects including damage to your workpiece or tools. If you are looking for high quality spot drills or center drills, you can find some amazing solid carbide options at Online Carbide. Their carbide tools are designed to offer the same performance as tools from other US manufacturers. You can visit their website at www.onlinecarbide.com to see a full list of their available drill bits and end mills. If you have any questions about the tools that they offer, you can reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted October 12, 2020 02:37

![]() December 5, 2019 05:54

December 5, 2019 05:54

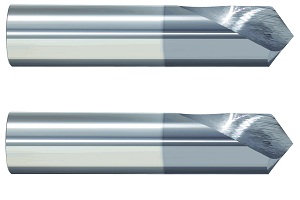

When it comes to machining components that need to have solid connections, you need to make sure that you have accurate thread mills. The process of thread milling requires making highly accurate cuts so that your components will be able to fit together as intended. If you want to ensure accurate results, you need to complete your work using Solid Carbide Thread Mills. Here at Online Carbide, we make all of our milling cutters to our exact standards using top of the line solid carbide stock. These tools are designed to perform the cuts you need within precise tolerances and can cut a diverse number of thread designs to meet any shop’s needs.

Thread milling is a tricky but necessary part of machining. This process used to only be completed using specialized tools call taps and dies. These tools can cut accurate threads, but often require the operator to cut the threads by hand, which can be cumbersome and time-consuming. Using thread mills is a great way to simplify this process.

Here at Online Carbide, we offer two styles of thread mills. The first style is our single pitch thread mills. These end mills are designed with a small shank and a round cutting head with a rough rhombus-shaped cross-section. These tools are suited to a wide range of thread cutting needs including medium to large internal threads of larger external threads, particularly on asymmetric components. They are also ideal for components that are not extremely stable, due to their small cutting surface. This makes them perfect for thin-walled parts or dealing with large overhangs. You can also use these single pitch mills to cut the same insert sizes, but with different thread pitches.

Our next option is our full form thread mills. These mills have a sturdy tapered cutting surface with threads and rows of triangular “teeth” between the threads. Unlike single pitch mills, these end mills are designed to complete your part’s threads using one 360-degree cut. As long as the thread pitch is identical, these end mills can cut multiple thread sizes with the same tool. They will also chamfer while they cut your threads.

We offer all of our solid carbide thread mills in a range of sizes. Our Single pitch thread mills are sold based on thread size and threads per inch. Our full form thread mills are divided based on UN, metric, NPT, and NPTF thread options. All of our thread mills are coated with a TiAlN layer to protect from heat and extend their tool life.

So if you work in a shop that regularly has to cut threads, it’s time to look into the high-quality solid carbide thread mills from Online Carbide. All of our cutting tools are made using the highest quality carbide stock and ground to exact tolerances using our robot FEC 5 Axis CNC grinders. If you have any questions about our inventory, feel free to reach out to a member of our team via phone at 630-238-1424 or email at sales@OnlineCarbide.com.

Posted December 5, 2019 05:54

![]() November 28, 2019 22:34

November 28, 2019 22:34

While machining harder materials like steel can but some serious wear on your end mills, people often underestimate how difficult machining soft aluminum can be. If you go into an aluminum milling project without the correct cutting tools, you may damage both your cutter and your workpiece. We have looked at the challenges aluminum can pose and have created the Best End Mills For Aluminum in order to help our customers machine with ease.

Here at Online Carbide, we are dedicated to providing our customers with top of the line carbide cutting tools. We use the same high-quality solid carbide stock as other industry leaders, we never offer carbide coated or tipped tools. We use robot fed 5 axis CNC grinders to produce our cutting tools to precise tolerances. This helps ensure that every tool we sell will perform as expected. We also only sell directly to our customers. These manufacturer direct prices will help you avoid the mark up that most stores put on cutting tools after purchasing them from the manufacturer.

There are several aspects of aluminum that can make it a tricky material to machine. The biggest concern when working with aluminum stems from the small chips that are produced. The chips from aluminum are so small they are basically a powder. This means that if the chips are difficult to evacuate from the cutting area. If too much aluminum powder builds up about your cutter, it can easily start to cake up back into a solid mass. If this occurs it can severely damage your end mill.

In order to help with chip evacuation, the best end mills for aluminum will have a lower flute count compared to tools for steel. This gives the chips more room to evacuate. We make our end mills using a 37-degree helix angle which is also intended to increase the evacuation rate. These features make it much easier to work on aluminum without worrying about unexpected tool failure.

The final feature that makes our end mills the best end mills for aluminum is the coating. We coat all of our tools intended for aluminum with a layer of zirconium nitride. This is a golden-colored ceramic coating that has extremely low surface friction, making it harder for chips to stick. It also helps to greatly increase the life of tools by protecting the tool’s cutting surfaces.

If you work in a shop that regularly deals with machining aluminum, you know how important it is to attack every job with the right tools. If you’re ready to upgrade to the best end mills for aluminum, it's time to visit us at Online Carbide. If you have any questions about our end mills for aluminum or any of our other products, feel free to contact a member of our team at sales@onlinecabide.com or call us weekdays between 8-5 CST at 630-238-1424.

Posted November 28, 2019 22:34

![]() November 1, 2019 02:02

November 1, 2019 02:02

Chamfer cutters are one of the most frequently used end mills in a machinist’s toolbox. This is because they are perfect for finishing projects and taking care of small details. Chamfering is the process of adding a flat surface as a transitional edge between two faces on an object. The most typical form of chamfering is at a 45° on a 90° corner. Though Chamfer Mills are specifically designed for adding a chamfer to your edges, they can serve many additional functions that you might not have considered.

One of the chamfer mills obvious functions is beveling an edge. Many people actually confuse a chamfer and a bevel. While a chamfer affects only the edge where your sides meet, a bevel affects an entire edge. How effective your chamfer cutter will be when beveling an edge depends on your workpiece. If the piece is thin enough, you can easily bevel the edge by orienting the tip of your chamfer mill along the bottom edge of your piece. If you are dealing with thicker material, you can achieve a bevel with multiple passes of your chamfering mill.

Deburring is another job perfectly suited to a chamfer mill. When your milling is complete, you are bound to have some stray burs left on your piece. By tracing the edges you just cut with your chamfering mill, you can avoid the time-consuming process of manually deburring your piece. You can also deburr using only a small portion of the cutting head, meaning the job can be done quickly with minimal wear to the cutter.

Another excellent way to get some more utility out of your chamfer cutters is to use them for spotting and countersinking. Long drill bits tend to have a bit of flexibility to them. This can easily cause them to wander instead of placing your hole exactly on target. By spot drilling a dimple to receive the bit, you can avoid these deflections that can easily ruin your workpiece. Once your hole is drilling, your chamfer mill can also be used to widen the top of your hole to add a countersink. Instead of using three separate tools to spot and countersink, you can get it done using only your trusty chamfering mill.

With all of these functions, it’s clear that having quality chamfer cutters on hand is crucial to getting your work done efficiently. At Online Carbide, we manufacture our solid carbide chamfer mills here in the USA. When you buy chamfer mills from us, you get the mills made to the same high standards as the major brands, but without dealing with markup from middle men. You can purchase our chamfering mills in ¼”, ?”, and ½” diameters with either 60° or 90° tip angles.

We are dedicated to making the best carbide cutting tools on the market. No matter what you need to get your next job done, you can trust Online Carbide to provide the quality milling tools your shop needs at an amazing price.

Posted November 1, 2019 02:02

![]() July 18, 2019 07:55

July 18, 2019 07:55

If your business involves milling machines, then you know that end mills and other carbide cutting tools are essential. These useful little components are what gives the business end of your mill its cutting power. Whether you’re working with wood or metal cutting machines, having a wide assortment of end mills will make finding the right tool for the job easier. When you need new end mills for your business, there are several factors to consider.

End mills will naturally wear over time. The level of this fatigue can be affected by the speeds and feeds you use, as well as the material you are milling. Even with the best possible settings, you will also notice a huge difference in tool fatigue based on where you buy your end mills. While cheap end mills can be found, typically from overseas manufacturers, these end mills are often constructed from low carbide grades. When these cheap end mills go up against a material as hard as stainless steel, the high temperatures will wear them down quickly. Quality tools made from high-quality carbide will outlast these cheap end mills every time.

When choosing a manufacturer for your carbide cutting tools, your best option will always be an American company that grinds their carbide tools from the highest-quality solid carbide. At Online Carbide, we specialize in making the best carbide tools right here in the US. We pride ourselves in using the same carbide stock and grinding tools as industry leaders, but at a fraction of the cost.

The reason you can buy our carbide tools for less is simply because when you buy from us, you are buying directly from the manufacturer. Most big brands sell their tools wholesale to middlemen, who then mark the products up before selling them to your shop. Instead of dealing with this unnecessary markup, Online Carbide offers our customers manufacturer direct pricing so you don’t have to overpay for the end mills you need.

With our assortment of end mills and drill bits, you will be able to find the perfect tool for any job. We offer the following categories of products: full form thread mills, single pitch thread mills, variable end mills, end mills for aluminum, 6 flute end mills, chamfer mills, drill mills, center drills, spot drills, stub drills, and jobber drills. You can find cutting tools with a carbide finish, as well as tools with treated cutting edges for increased performance and extended tool life.

Next time your business needs carbide cutting tools, trust a quality manufacturer. At Online Carbide, we know our mills are second to none and our prices will beat out the major brands. Whether you need a new chamfer bit or a variable mill to power through steel, our products will amaze you with their resilience. Don’t overpay for quality or try to save by buying cheap. Your shop deserves only the best end mills, and that’s exactly what Online Carbide is here to offer.

Posted July 18, 2019 07:55

![]() July 16, 2019 07:41

July 16, 2019 07:41

There are quite a few companies which are Drill Bit manufacturers but none like Online Carbide. The engineers at Online Carbide weren’t going to settle for the average, ordinary Drill Bit. They wanted a superior product with enhanced and upgraded materials and maximum longevity. In other words, the engineers wanted to design, engineer, and manufacture the best Drill Bits available. They did it.

Making the Most Out of the Best

Manufacturing a quality machine tool like a Drill Bit isn’t exactly rocket science, however, there are some significant differences between products and machine shops, production floor managers, and manufacturing plant managers know the differences. What those customers want is a Drill Bit that doesn’t flex or bend, has cutting edges that will last longer, and doesn’t cost an arm and a leg. Online Carbide meets all those requirements and more. The engineers at Online Carbide decided to utilize10% Cobalt Micrograin which made their Drill Bits rigid. They also incorporate materials like Zirconium Nitride, Titanium Aluminum Nitride, Aluminum Chromium Nitride, and Bright Finish which keep cutting edges sharp and longer lasting. And they sell their carbide tools at factory direct prices that save their customers a lot of money.

Online Carbide are the Drill Bit Manufacturers With All the Right Sizes

Producing a full line of Drill Bits for machining operations gives Online Carbide an edge over many of their competitors who only manufacture a limited number of designs and sizes. Online Carbide offers Drill Bits in the following configurations:

- Drill Mills

- Center Drills

- Spot Drills

- Stub Drills

- Jobber Drills

Each Drill Bit style comes in sizes from 1/16 inch up to 1 inch, increasing in size by 1/16th inch increments.

Online Carbide are the Drill Bit Manufacturers with the Right Prices

Selling factory direct to customers means there is no middleman markups or handling charges. Those added costs can raise the price of machine tools by 40 to 50% or more. When customers purchase their Drill Bits and other machine tools from Online Carbide, they also get free shipping in the continental United States for orders over $250. And customers can check out Online Carbide’s website at www.onlinecarbide.com to find sales and product specials in addition to their already low prices. Excellent products at great prices with free shipping makes Online Carbide the best resource for all machine tools.

Great Customer Service Seals the Deal

One-man machine shops and machining operations that span entire production plants both count on the same thing when purchasing their Drill Bits or other machining tools - great customer support. They know a company that not only manufactures excellent carbide tools at low prices but that can also support their customers with top-shelf customer service will be their first choice when it comes time to order what they need. Online Carbide connects with customers easily by using their email contact at sales@onlinecarbide.com or having customers call them at 630-238-1424 Monday through Friday from 8am to 5pm Central Standard Time.

Posted July 16, 2019 07:41

![]() March 20, 2019 07:44

March 20, 2019 07:44

America is a nation of possibility, where every day, hard-working people put in an honest day’s work and return home to their families. For many of these people, work is grinding every day, difficult, challenging and often requires exceptional strength to keep everything moving and operating properly.

In carbide drilling, you want parts that are as tough as you are. You want rugged and tested drill bits and stub drills to get the job done right the first time and leave you with the sense of security that you can cross it off your to-do list for good.

At Online Carbide, we’re an American company for the American people. What does that mean? It means that we want to provide the best for you because you deserve the best. We want to provide you with tremendous value. We want to give you the quality you deserve in a price that is set by the manufacturer, not a distributor. And we offer a large range of products to do that.

Our stub drills come in various sizes and styles to tackle any job.

Our fractional stub drills range from 1/16” to 3/4". Fractional stub drill bits are applicably named because they come in fractional increments.

Our letter stub drills range from Size A (.2340) to Z (.4130). These are very common twist drill bits with the sizes ranging from smallest to largest – A is the smallest bit we offer.

Our wire size stub drills range from 52 (.0635) to 1 (.2280).

Our metric stub drills range from 2.0MM to 12.5MM. These drill bits are measured in standard metric lengths with 2.0MM being the smallest.

Whatever the job is, large or small, simple and easy, or challenging and tough, we have the parts you need.

All of the drill bits sold by Online Carbide are made in the USA and we take pride in making sure that the quality we offer is second-to-none. We are always expanding our range and product catalog. We want to go above and beyond for you.

If you have any questions about our products or our website, feel free to contact us. We are available by phone from 8 a.m. to 5 p.m. CST and by email at sales@onlinecarbide.com.

Order online with us today. We accept all major credit cards and PayPal. Many of our items ship on the same day so you can get them as soon as possible. We will contact you regarding shipping and delivery information after you place your order. Contact us with any question about the items we have in stock.

Everyone wants to get the right product with the most value. We care about providing that experience for you. You work hard and expect the best in your shopping experience. Let Online Carbide be your source for all of your carbide cutting tool needs, with superior quality, customer service, and efficient costs. That is the American way, and we strive to be just a small part of that, making life better for our fellow Americans.

Posted March 20, 2019 07:44