![]() September 9, 2020 02:31

September 9, 2020 02:31

End mills are extremely useful tools, but they can easily become worn out from extensive milling. Between the natural fatigue to cutting edges and the stress of the heat that comes with high speed machining can easily cause premature tool failure. In order to better protect their tools, many manufacturers offer options that have been treated with specialized coatings like Zirconium Nitride(ZrN) and Titanium Aluminum Nitride(TiAlN). TiAlN coated end mills and drill bits offer a much longer lifespan and edge retention when compared to uncoated tools.

The highest quality end mills are manufactured from solid carbide stock. Tool carbide is a mixture of powdered carbide ceramic and a binding metal, typically cobalt. This material is particularly well suited for end mills because it is both extremely rigid and holds an edge remarkably well. Other end mill materials like high speed steel alloys are able to maintain hard edges even at high temperatures, but they can still lose their temper. Because the edge strength of carbide tools is the result of the material’s ceramic content, high temperatures will not significantly impact their ability to hold their cutting edges.

Despite these advantages over conventional solid metal tools, carbide tools can still suffer from heat fatigue. When operating at high speeds, especially over long periods of time, your carbide tools will wear down. This typically takes longer than comparable steel tools, but it can affect your productivity if you experience a sudden tool failure or you are working with tools that are not sufficiently sharp. One way to extend the working life of your tools is to purchase options that have been treated with a protective coating.

One of the most popular tool coatings for extending the working life of milling cutters is TiAlN. This material is deposited onto tools using specialized vapor deposition processes where the coating material is vaporized and then resolidified on the surface of the tool to create a thin, consistent, and extremely secure coating. These coatings are typically only one micron thick and manage to provide protection against heat by creating an insulating layer of aluminum oxide on the surface of TiAlN coated end mills.

This layer of Al2O3 helps to deflect heat into the chips and away from the body of the cutter. The coating itself is also very hard, which helps maintain sharp edges and avoid breakage. It has even been shown that TiAlN coatings can continue to get harder over time as the tools are continuously heated. This makes them a great option for any tool that is regularly subjected to high speeds and temperatures.

If you are looking for TiAlN coated end mills for your shop, Online Carbide has plenty of options for you. They are an American tool manufacturer specializing in solid carbide end mills and drill bits. They offer tools with polished carbide finishes as well as options that are coated in TiAlN to help extend their working life.

Posted September 9, 2020 02:31

![]() September 4, 2020 07:52

September 4, 2020 07:52

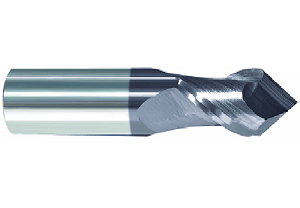

One of the biggest hurdles when it comes to machining components is time. Between having to run steel tools at slower speeds and the need to change out tools to perform a wide range of functions, machining time can really add up. If you are looking to cut down on tool changes, you need to consider using drill mills when you are machining. These versatile milling cutters can perform a wide range of tasks, making them an ideal way to speed up production.

If you could not guess it from the name, a drill mill is a tool that combines aspects of drill bits and end mills. These tools end in a sharp tip similar to a drill bit, but the flutes along the body of the mill resemble the side milling flutes of an end mill. This combination of characteristics allow drill mills to tackle a wider range of milling operations than either a drill bit or end mill could complete by itself.

One of the biggest advantages of a drill mill over an end mill is the fact that they can be used to actually drill into material. Most end mills are only designed to perform side milling cuts so axial cutting just is not an option. Because of the drill bit like tip, drill mills can perform a few actions that your average square or ball ended mill just cannot complete. This includes tasks like spot drilling and drilling small holes in your workpiece. Normally you would have to perform tool changes if you wanted to complete these tasks after side milling, but not willwith drill mills.

When it comes to side milling, the drill mill can also perform. Obviously the tip of the drill mill means that they can only side mill sections that terminate in a v shaped notch or create V shaped notches in your work piece. These unique cutting tools can also be used to chamfer and bevel edges. The pointed tip on these tools is also perfect for deburring your workpiece when you are ready to take it off the mill.

In order to get the most out of your drill mills and other milling cutters, you need to consider the materials used in their construction. High speed steel alloys have become a popular option because they are affordable and can operate at higher speeds than other steel alloys without losing their temper. Despite this fact, steel tools just cannot beat the performance of solid carbide cutters. Carbide can hold an edge longer and run at faster speeds than steel tools. Treating tools with protective coatings like titanium aluminum nitride will also help extend the life of your tools.

If you are looking for high quality solid carbide drill mills, you need to check out the options from Online Carbide. They machine high quality carbide cutters including drill bits and a wide range of end mills from standard options to specialized cutters like thread mills. If you have any questions about their tools, feel free to contact a member of their team by sending an email to sales@onlinecarbide.com.

Posted September 4, 2020 07:52

![]() September 4, 2020 07:44

September 4, 2020 07:44

CNC milling machines are becoming one of the most commonplace manufacturing tools when it comes to the production of custom components. These computer guided cutters are able to create parts from virtually any material, making them an invaluable resource for manufacturers. When it comes to extending the working life of tools or cutting into hard materials like steel or cast iron, solid carbide cutting tools will provide the best results.

Some of the most common tools are manufacturers from high speed steel alloys. These materials are designed to handle higher speeds and feeds than standard steel tools, but they cannot go as fast as carbide tools. Any fully metallic tool is subject to the physical properties of metals, including heat tempering. Once metal is run through the proper temperature cycles, it will become tempered. Tempered metal has a more uniform hardness and less brittle cutting edges than untemperated metal.

At high enough speeds, any metallic tool is capable of losing its temper and the hardness of its cutting edges. This is what makes carbide cutting tools so important. Carbide tools are made from a combination of cobalt metal and powdered micrograins of tungsten carbide ceramic. While the metal components of the tool may soften with heat, the ceramic content within carbide tools help to stabilize their cutting edges. Tungsten carbide is twice as dense and twice as rigid at steel and stable at almost any temperature.

This makes carbide milling cutters the perfect tool for operating at the high speeds so shops can minimize production times and work with a wider range of materials. If you are planning on ordering new carbide end mills or drill bits for your shop, it is important to consider the source you are purchasing them from. There are different carbide grades and cheaply manufactured tools are often constructed from lower quality materials.

One way to ensure high quality tools is to avoid ordering from overseas. American manufacturers not only consistently produce high quality tools, but they are also available when you need them. If you are looking for a reliable manufacturer, check out Online Carbide. They are an American end mill and drill bit manufacturer that uses high quality carbide stock and precision grinders to make incredibly accurate tools. They offer all of their products at manufacturer direct pricing so customers can save big on high quality products.

So if your shop is in need of new carbide cutting tools, check out www.OnlineCarbide.com. Their product line includes standard end mills, drill mills, thread mills, and several types of drill bits. They offer both polished carbide tools and tools coated with finishes like zirconium nitride and titanium aluminum nitride. These coatings help to protect your tools and extend their working life. If you have any questions about their products or placing an order, you can contact a member of the Online Carbide team by calling 630-238-1424 or sending an email to sales@onlinecarbide.com.

Posted September 4, 2020 07:44

![]() September 3, 2020 04:29

September 3, 2020 04:29

Machining with a milling machine is a combination of a violent cutting action along with delicate control. To machine accurate parts, you need tools that operate at precise tolerances. Tools not only have to be sharp, but they also need the strength and rigidity to handle the strain of high speed machining. Carbide cutting tools are one of the best milling cutters when it comes to performance and long term edge retention.

What is Carbide?

Solid carbide is a specialized tool material. While it may look similar to steel and other alloys, tool carbide is actually a cemented material made by combining incredibly hard powdered carbide ceramic with a strong binding metal. By itself tungsten carbide is a grey powdered ceramic material that cannot be used to make tools on its own. Carbide is a pretty amazing material because it is twice as strong and twice as rigid as steel.

By mixing this powdered material with a binding metal, carbide tool stock gets positive traits from both materials. The metal portion of the material provides strength and flexibility while the ceramic portion provides rigidity and powerful edge retention. Because carbide is a ceramic, it can not lose its temper. This means that it is perfectly suited for high speed and high temperature operations where purely metallic tools would soften and lose their sharp cutting edges.

Using Carbide Cutters

Carbide cutting tools are suited for a wide range of milling applications. Because they can handle the heat that comes with friction, you can operate these tools at a wide range of speeds and feeds. Depending on the design of the cutter in question, you can use carbide tools for side milling, drilling, thread cutting, or other applications like milling aluminum.

Protecting Carbide Tools

Despite the fact that these tools are stronger than cutters constructed from materials such as high speed steel alloys, carbide tools still wear down over time. In order to protect tools, manufacturers will often treat them with specialized coatings.

Coatings like titanium aluminum nitride (TiAlN) are commonly used because they are extremely hard and help insulate end mills during use. TiAlN actually creates a fine layer of aluminum oxide on the surface of the cutter that helps to deflect heat away from the body of the tool so heat is lost with the chips instead of building on the cutting edges. These tools will obviously still get hot during use, but they should last much longer than untreated tools.

Finding Quality End Mills

If you are looking for some high quality carbide cutting tools, it’s worth looking into tools made by American manufacturers. Not only are these tools made to exact tolerances using quality materials, but working with manufacturers in your own country gives you easy access to customer service teams during your business hours. Online Carbide is an excellent tool manufacturer that machines high quality cutting tools which they sell directly to users at manufacturer direct prices. If you want amazing tools at great prices, visit their website at www.onlinecarbide.com.

Posted September 3, 2020 04:29

![]() August 28, 2020 08:26

August 28, 2020 08:26

Machining can be a loud and slow process. Metal cutting into metal at high speeds is a loud and violent process. If pushed too quickly or run at too high a speed, your cutting tools can quickly break or wear down, potentially damaging your tools and your workpiece. The variable end mill was designed to run faster than other tools without creating nearly as much chatter.

Tool chatter is the sound that is produced by machining. This is influenced by a number of factors, but is mostly affected by tool speed. The faster a tool spins, the more it will naturally oscillate. Image spinning a piece of string between your palms. The faster you go, the more the string spins out away from its central axis. The same thing is happening to your tools but on a much smaller scale.

As the tool oscillates, you will begin to hear the chatter caused by the tiny changes in impact pressure across your work area. Not only is this sonically unpleasant, but it can also potentially damage your equipment. Most operator’s solution to chatter is to lower the speeds and feeds used during production, but this comes with the cost of slowing down production. One other way to combat this issue is the use of variable end mills.

Variable end mills are designed to address the issue of tool chatter for CNC machining in a unique way. Instead of having perfectly uniform flute spacing, i.e. 90 degrees between the cutting edges of a four flute mill, the cutting edges are all spaces with slight asymmetry. This helps to prevent tool chatter by avoiding the other source of tool oscillation, the regular timing between cuts.

To give another simple analogy, imagine pushing a child on a swing. If you apply the same amount of force at the same time interval, the arc of the swing will continue to grow and grow at a predictable rate. The striking of cutting edges against the workpiece at regular intervals does the same thing to the oscillation of your milling cutters, building it constantly.

Instead of relying on even spaced flutes, variable end mills use a different tool design with irregular spacing to change the timing between strikes. This helps to break the end mill’s ability to oscillate and provides the ability for users to speed up production without creating more deafening tool chatter.

If you are looking to cut down on production times and chatter, variable end mills could be the perfect tool for your shop. If you are looking for an American manufacturer of high quality drill bits and end mills, including variable helix end mills, Online Carbide has the tools you need. Their solid carbide end mills are precision machined from high quality stock and they provide incredible results. If you have any questions about any of the tools they offer, feel free to reach out to a member of their team by calling 630.238.1424 or sending an email to sales@onlinecarbide.com.

Posted August 28, 2020 08:26

![]() June 15, 2020 08:49

June 15, 2020 08:49

When you are machining products in your shop, you know the kind of fatigue that regular usage can put on your cutting tools. With too much use, the flutes of your drill bits will eventually dull. This can lead to poor performance and even tool breakage. To make sure that you are getting the most out of your drill bits and other cutting tools, you need to ensure that you are buying them from a quality drill bit manufacturer.

Drill bits come in all shapes and sizes, particularly for machining. This leads to machining shops requiring a large selection of drill bits in order to perform all of the necessary cuts. Some holes, particularly in harder materials like metal, may even require several drill bits to accomplish. First the location of the hole needs to be short drilled before it can actually be drilled to the intended width and depth. This helps to ensure a clean hole without damaging the workpiece.

The reason for using multiple drill bits is to combat the issue of drill bits “drifting” off of their intended location. The best way to avoid this is to limit the length of the drill bit being used. A short drill bit, like a spot drill, is designed to have almost no drift, making it ideal for marking the location of holes in your work piece. Sadly, their short length means they have no cutting flutes beyond the point and they can only produce a small divot. This starting divot means it is easy to drill your holes without having to worry about your longer stub or jobber length drill bits deflecting off of your material and missing the mark.

The best bits come from carbide drill bit manufacturers. Carbide not only retains a cutting edge better than other tool materials, but it is also more stable. This stability makes carbide the ideal drill bit material. Even at longer lengths, your carbide tools will drift less than other bits. This is because high quality tool carbide is a combination of cobalt metal and powdered ceramic tungsten carbide. This carbide material is twice as dense and rigid as steel. Also, due to being constructed with ceramic, carbide tools are more resistant to heat fatigue and dulling than metal tools.

You can find a large selection of high quality carbide drill bits when you visit www.Onlinecarbide.com. They are a solid carbide end mill and drill bit manufacturer dedicated to producing cutting tools that are built to last. They construct their tools using advanced 5 axis CNC grinders like other leaders in the cutting tool industry. Unlike those other manufacturers, Online Carbide offers its tools at manufacturer direct pricing so their customers can enjoy incredible savings. If you have any questions about their tools or their ordering process, you can call 630.238.1424 between 8 am and 5 pm CST or you can send your questions in an email to sales@onlinecarbide.com.

Posted June 15, 2020 08:49

![]() June 15, 2020 07:37

June 15, 2020 07:37

As many machinists and shop owners know you can find carbide end mill sets online for extremely low prices. Most of these tools are shipped from overseas and, unsurprisingly, you end up getting what you pay for. All tools will wear down and break over time, but you can influence how long that process takes based on where you purchase your tools.

Carbide is the preferred material for milling cutters. It is both strong and dense, meaning carbide tools can hold their cutting edges for a long time. In its raw form, carbide is actually a ceramic material. Tungsten carbide, one of the most common tool carbides, is typically manufactured as a grey powder. In order to create tools that take advantage of this material’s strengths, this ceramic powder has to be suspended in a metal bonding agent. The combined metal-ceramic sintered material is what we know as tool carbide.

Many of the cheap carbide end mill sets you see online are cheap for a reason. Typically material quality is one of the first things to go when manufacturers cut costs. This might mean that these overseas manufacturers are selling tools that are only carbide tipped/coated instead of being solid carbide. Even if the tools are solid carbide, there are different grades of carbide and the low price probably means low quality carbide.

This means that you should expect these tools to quickly dull and fail. The composition of carbide tools makes it hard for them to lose their cutting edge, but low quality carbide can have an uneven composition that will erode differently over time, creating weak points that can fail. In some cases, these weak points might even result in cracking and failure of the cutter in a short period of time compared to a well constructed end mill.

If you want carbide end mills that are going to last, buying from an American manufacturer is a great way to ensure a high quality performance. Unlike overseas buyers, you can trust the fact that industry standards in the states means that solid carbide tools will be real solid carbide. You will also get to enjoy one thing that you can not typically find when dealing with overseas vendors, customer service. American manufacturers are on your schedule, speak your language, and they want to retain your business.

To see a huge selection of precision made solid carbide cutting tools, check out www.OnlineCarbide.com. You might have to spend a little more if you want to create your own carbide end mill set, but the difference in quality will make a big difference in the long run over buying cheap tools from overseas. If you have any questions about the tools they offer, you can reach a member of the Online Carbide team by calling 630.238.1424 between the hours of 8 am and 5 pm CST or send an email to sales@onlinecarbide.com.

Posted June 15, 2020 07:37

![]() June 15, 2020 06:58

June 15, 2020 06:58

When it comes to running a machining shop, time matters. Having to do constant tool changes on your milling machine can be both annoying and time consuming, but it is important to always use the proper end mill for every task you are trying to accomplish. Here at Online Carbide, we are dedicated to producing high quality carbide drill bits and end mills. They also have drill mills for sale which can help machinists perform several tasks with a single cutter.

Drill mills are, as their name might suggest, a cutting tool that combines features of drill bits and end mills to become incredibly versatile. Most end mills typically end in a squared off of rounded end, unless they serve a specialty purpose. Drill mills end in a drill bit-like point for axial cutting and they have a flute structure designed for side milling.

The flutes on drill mills make it possible to perfect side milling, though they will produce an angled cut towards the bottom. This may actually be desirable for projects that require a notch cut. If you are machining softer materials like wood, or your project doesn’t require a lot of side milling, you may be able to complete the entire project using only a drill mill.

This makes it easy to perform a wide number of operations using one tool. The point on the point of a drill mill is perfect for performing fine jobs like chamfering, beveling, spot drilling, even drilling small holes. Traditional end mills are great for side cutting, but they cannot complete axial cuts. Because of their tipped points, a drill mill can easily perform simple drilling operations. You can also use them to spot drill hole locations so you can work faster when you use your drill bits.

In order to hold up to drilling into tough materials, the drill mills at Online Carbide are manufactured in the US using quality solid carbide stock. The drill mills for sale on their website include 2 and 4 flute versions. You can also choose between a 60 or 90 degree angle for the tip of the drill mill. Because they are constructed from solid carbide, they retain their cutting edge and are able to cut harder materials like steel. Unlike tools made from steel, carbide tools can handle the heat and friction that comes with high speed machining.

So if you are ready to save some time while working on your next machining project, visit Online Carbide and check out their drill mills for sale. One of these unique cutting tools can help you avoid tool changes so you can complete your projects quickly and efficiently. To see these versatile cutting tools and several other drill bits and end mills, check out their store at www.onlinecarbide.com. If you have any questions, you can reach out to their team by calling 630.238.1424 or sending an email to sales@onlinecarbide.com.

Posted June 15, 2020 06:58

![]() June 15, 2020 05:57

June 15, 2020 05:57

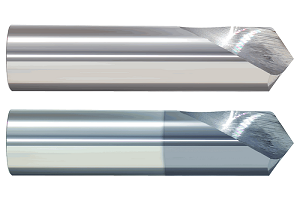

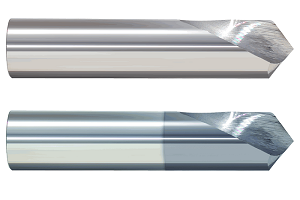

Drill mills for precision milling applications are very common and actually fairly useful for a wide number of jobs. From the name it might sound like their main practical use is for drilling a hole through a surface, and they certainly can be used to do so. At the same time, however, they can be used to perform a great number of other tasks.

Typically found with points of 60 or 90 degrees, drill mills can be used to drill a hole, which is a necessary function of a drill mill. Drill mills can also be used to side mill a groove or to do profiling work. On top of drilling holes through a medium, drill mills can also be used to spot, chamfer and profile material, to name a few other functions.

The process of spotting is something in line with its name. It is a way to create a ‘spot’ on the surface that is going to be machined. The reason for spotting is to create a divot in a material that will serve as a sort of guide for the mill that will subsequently be used to machine a surface. Without a spot, a mill has a greater chance of walking along a surface or of being damaged. Spotting must always produce a divot with a greater angle (or the same angle) as the next bit to be used, or the next bit may be damaged.

Precision milling can leave very sharp edges on the materials that are machined. As a result, many machinists will chamfer a hole in order to soften out the sharp edges, or even to produce a countersink. At its most basic, chamfering is the process of creating a soft sided slope around the circumference of a drilled incision. That has the first function of removing any remaining burrs or sharp edges, and the second of producing a countersink, if one is needed.

Some drill mills are suitable for profiling as well. Profiling is, as the name sounds, removing a profiled shape from a material, or cutting it to shape. It is a rough process but it results in the desired shape to be machined into or from a material such as aluminum stock.

Solid carbide drill mills are often found in uncoated and coated varieties. For example, some carbide drill mills are coated in TiAlN, or titanium aluminum nitride. This coating forms a protective aluminum oxide layer during use that reflects heat back into the chips that are milled away, protecting the mill and the piece being worked.

If you need drill mills or other cutting tools for any of these or other applications, be sure to visit OnlineCarbide.com. Online Carbide offers coated and uncoated drill mills along with end mills, thread mills, chamfer and spot mills and more for your precision milling applications. Best of all, their prices are nearly impossible to beat and their mills are all made right here in the United States. If high quality and low prices for the best available drill mills are two prerequisites for you, then visit OnlineCarbide.com today.

Posted June 15, 2020 05:57

![]() June 15, 2020 04:01

June 15, 2020 04:01

If you work with milling machines, you have either experienced or heard horror stories about what can happen when you use low quality end mills. Many “carbide” end mills from overseas lower their prices by selling carbide coated tools or tools made from lower quality carbide stock. In order to avoid the short lifespan and potential for sudden failure that comes with these cheap tools, you need to make sure you are ordering from quality solid carbide end mills manufacturers.

End mills and drill bits are tools that undergo a great deal of strain, especially when used to cut metal. If you are looking for mill cutters that can handle even the toughest jobs, you need to check out Online Carbide’s solid carbide cutting tools. Online Carbide is an American Solid Carbide End Mill Manufacturer of high quality cutting tools. They use solid carbide stock and advanced CNC grinders to create precision cutters for your mill.

Carbide is one of the best tooling materials for the production of end mills and similar high speed milling tools. Because this high speed creates large amounts of friction, milling cutters have to be able to resist high levels of heat without losing their cutting edges. Alloys like high speed steel can handle the heat, but you cannot beat carbide tooling for their incredible lifespan.

Carbide’s strengths come from its unique composition. Based solely on appearances, carbide tools appear to have a solid metal construction. In reality, tool carbide is a sintered material created by combining powdered ceramic carbide with a metal binder, typically cobalt. Under magnification, these tools look similar to concrete with the metal acting as the cement and the carbide powder serving as the aggregate.

The small bits of carbide “aggregate” gives carbide tools some incredible properties. This material is twice as dense and rigid as steel, but it can not lose its temper at high temperatures because it is not metallic. This makes it possible for carbide end mills and drill bits to keep their cutting edges for longer periods of time. If you are tired of wearing out steel and lower quality carbide tools, it is time to start buying directly from a carbide tool manufacturer.

Online Carbide only offers their tools directly to users. This means that you can always find manufacturer direct pricing when you are shopping on their website. Their inventory includes a wide range of tools including thread mills, standard mills, variable flute end mills, end mills for aluminum, spot drills, jobber drills, and more!

You can see their full product catalog when you visit www.onlinecarbide.com. When choosing a solid carbide end mills manufacturer, don’t overspend on big name brands when you can find great deals on tools made from the same material with the same advanced grinders. If you have any questions about their tools, you can reach a member of the Online Carbide team by calling 630.238.1424 between 8 a.m. and 5 p.m. CST or sending and email to sales@onlinecarbide.com.

Posted June 15, 2020 04:01

![]() June 15, 2020 03:28

June 15, 2020 03:28

Machining can take a lot of time, especially when you are operating at lower speeds and feeds. One way to speed up working time is to use variable flute end mills. These unique cutting tools look like your standard end mill, but with a few important distinctions when it comes to flute design. If you have had to lower your speeds and feeds to avoid chatter and you want to get back to milling quickly, variable helix end mills can help you speed up your operation without the risk experienced with traditional end mills.

A typical end mill is designed with symmetry in mind. When you look at the bottom of a four flute end mill, the flutes all meet at a perfect 90 degree angle. This means that the space between cuts is identical and, at a consistent speed, the period time between every cutting edge striking the workpiece is also identical. The consistent timing between cuts can produce a natural oscillation in the cutter itself. This will cause the tool to shake and, at high enough speeds, this can cause loud chatter.

Tool chatter is not only extremely loud, but it can also damage the cutter and your workpiece. In order to lower the natural oscillation of an end mill, variable flute end mills have flutes that do not meet with perfect symmetry. For example, a four flute variable end mill would not have flutes that met at perfect 90 degree angles. Instead it would have four different angles, which produce a unique effect.

Because the spacing and timing between each cut is not identical, the tool does not build to a natural oscillation. The inconsistent timing instead helps to break up the natural oscillation the previous cute was attempting to build. This leads to end mills that can operate at higher speeds and feeds than conventional cutting tools. Variable end mills operate quickly and quietly, making them a great choice for high material removal.

If you are looking for quality end mills, check out the operations at Online Carbide. They are an American manufacturer of end mills and drill bits ground from high quality carbide stock. Their variable end mills are precision engineered to offer top of the line performance. All of their variable end mills are also coated in a protective layer of titanium aluminium nitride. This TiAlN layer helps to protect the end mill from heat while also retaining the cutting edge of your tool’s flutes.

If you want to see all of the variable flute end mills that Online Carbide offers, visit their website at www.onlinecarbide.com. Instead of dealing with middlemen, Online Carbide sells directly to consumers for incredible savings. You can find all of the end mills and drill bits that your shop needs in their shop. If you have any questions about their tools, you can reach out to a member of their team by sending an email to sale@onlinecarbide.com.

Posted June 15, 2020 03:28

![]() June 11, 2020 06:03

June 11, 2020 06:03

Precision drilling and machining can seem more complex than it really is, with many specialized bits and processes making up the whole. While together they can be intimidating, typically they can be reduced down to relatively simple fundamentals.

Spot drills are one example of this. Looking through a catalog of precision mills one will uncover a number of other specialized mills like chamfer mills, thread mills, variable end mills and spot drills. Each of them performs a highly prescriptive task, and spot drills are no exception.

So what is a spot drill used for? At the simplest level, spot drills are used to create a spot - hence the name - that serves as a guide for the mill that will be used to drill through a material.

Why create a spot? Well, depending on many factors, like the hardness of a material or slickness of the surface being drilled, a mill can walk or slip when being used. That would entirely counteract the purpose of precision drilling, which is to make a clear, extremely precise cut into a surface. Spotting a surface with a spot drill is a method taken as a precaution to prevent another bit from walking, traveling unduly over a surface or even from making a rough cut.

Not just any spot drill can be used, however. Due to the high speeds and great forces that are imparted to mills, a carbide bit must contact a surface at a very precise angle in order to prevent damaging itself or the material being worked. A spot drill should create a divot in the material being worked that is the same or a larger point angle than the drill that will subsequently be used. If the angle of the divot created is too sharp, it can damage or destroy the drill that next touches it.

A spot drill can also be used to create a chamfer in a surface. Sometimes a specialized chamfer mill is used for that purpose. A chamfer is a small recess worked into a surface so that joining materials such as screws will sit flush on the surface, which is a requirement in some applications. Keep in mind however that in order to create a chamfer with a spot drill, the spot drill must be slightly wider than the drill making the next hole.

To find the best spot drills and other carbide cutting tools that money can buy, take a trip to OnlineCarbide.com. Online Carbide offers carbide drills such as drill mills, thread mills, end mills, spot drill, chamfer mills and more at amazing prices. By selling directly to their customers instead of through a drawn out supply chain, they can keep prices down without sacrificing quality. In fact, all of Online Carbides mills and drills are produced right in the United States of America to extremely exacting standards. It’s like getting more for less, and that’s something anyone can get behind. Visit their site today to see their full line of carbide cutting tools.

Posted June 11, 2020 06:03

![]() June 1, 2020 01:52

June 1, 2020 01:52

MAchining and milling are extremely precise operations. They are precise not only in the fine details that CNC machining can create or bring out on a surface, but they are also extremely precise in the tools that must be used in conjunction with the materials being machined. Milling and machining are even so prescriptive as to go so far as to specify when such end mills should be used on what surfaces and even what coatings are most appropriate.

The point being that machining is extremely precise, you may have come across chamfer mills and wondered what their purpose was. If you are unfamiliar with machining, consider this a primer.

Some mills leave a rough or sharp edge, sometimes leaving burrs, on the surface of the materials being worked. Using Chamfer Mills is one way to help eliminate leaving a sharp edge on a surface that must be left smooth.

For example, if you’re performing a relatively simple machining operation like drilling a clean hole through a metal, the edges of that hole might be left very sharp. Chamfer mills can be used to create a countersink around the hole to smooth out, or entirely eliminate any sharp edges that were left behind.

If the entire edge of a machined piece, and not just a hole, is sharp or covered in burrs, using a chamfer mill for deburring can save a lot of time and pain. Whereas it would take a fair amount of time and a lot of labor to manually deburr an edge, using chamfer mills to chamfer or bevel an edge can do so and remove any burrs that were there in the process.

Speaking of which, creating a chamfer or a bevel is another use of chamfer mills. A chamfer is an edge that is slightly angled but left with a portion squared, whereas a bevel is angled all the way across the face. In cross-section, it would appear to be an angled cut rather than a square edge.

Those are some of the essential functions of chamfer mills when used with chamfer cutters. It’s simply enough, but they perform very important functions for machinists when smooth surfaces or edges are required in accordance with any specifications.

If you already knew what chamfer mills were and just needed to find some for your projects, then you have it easy - just visit Online Carbide. Online Carbide is your chief source for carbide cutting tools at amazingly low prices.

Online Carbide offers some of the best carbide cutting tools in the industry, selling them directly to customers. By eliminating many of the links in the supply chain, they are able to keep costs down without compromising quality. In fact, they sell many of the same tools as competitors, only at lower rates.

Better yet, all of their tools are made right here in the United States to ensure quality, finish and customer satisfaction. Visit their site, Online Carbide, today to find the chamfer mills and any other carbide cutting tools you need for your projects.

Posted June 1, 2020 01:52

![]() May 12, 2020 12:24

May 12, 2020 12:24

The process of creating threaded connections is essential for modern machining. Threading parts allows a secure connection between components using bolts. For decades, threading components had to be done using specialized tap and die cutting tools. Now, thanks to advances in milling technology, Solid Carbide Thread Mills can achieve the same results as these traditional tools, but in a fraction of the time.

There are two different types of thread milling cutters. The first and most versatile option is the single pitch thread mill. These tools contain a small disc shaped cutting head that is designed to cut the full length of the thread. This process takes more time, as the cutter has to pass through the entire threaded surface. These tools are also perfect for working on delicate pieces, as it has a smaller cutting surface which produces less friction while in use.

In addition to single pitch end mills, you can also purchase full form thread mills. These tools resemble a thread cutting tap, but the teeth along the cutter are arranged in parallel rows instead of being arranged helically. In order to create a thread, the tool is moved the distance of one thread pitch while it makes its cut. This creates a helical pattern nowhere every row of teeth completes the cut that the row beneath them began. This makes full form thread mills the fastest option for completing any thread milling task. These cutters can be extremely versatile, though a single tool is restricted to cutting threads with a uniform pitch.

In order to get the most out of your thread mills, it is important to choose solid carbide thread mills. There are plenty of materials used to make end mills, including alloys like high speed steel. Sadly, these tools just cannot match the edge retention, density, and hardness of carbide.

Carbide tools are made by combining dense and strong powdered carbide ceramics with a binding metal such as cobalt. This creates a material that is truly superior to the sum of its parts. A carbide thread mill has the strength and durability of a metal tool while maintaining the hardness and edge retention of a ceramic.

To help these tools last even longer, many manufacturers treat their end mills with protective coatings like titanium aluminum nitride. This coating helps to form a protective coating that deflects heat away from the cutter, lengthening the lifespan of the tool. TiAlN coatings have the unique property that results increases its thermal insulating effect the hotter the end mill becomes.

So if you are looking for high quality solid carbide thread mills, visit www.Onlinecarbide.com. Online Carbide is an American manufacturer of high quality milling cutters and drill bits. Their single pitch and full form thread mills are made using high quality carbide stock and they are treated with TiAlN to offer the maximum lifespan. If you have any questions about the tools they offer, you can contact a member of the Online Carbide team by calling 630-238-1424 or sending an email to sales@onlinecarbide.com.

Posted May 12, 2020 12:24

![]() May 6, 2020 00:12

May 6, 2020 00:12

Carbide cutting tools can offer machinists a lot of benefits of machinists who need to create the most precise cuts as possible. Not only do carbide end mills make it possible to make extremely precise marks and cuts on a surface being worked, but certain carbide mills offer additional benefits over the ability to make very precise cuts.

One of the reasons that carbide end mills are advantageous at making very precise cuts is their ability to hold a very fine edge for a long time. Because of their superior hardness, carbide tools will stay sharp for much longer than other conventional mills. Carbide is a compound created of carbon and a metal binder, oftentimes tungsten or cobalt. This combination of elements takes the strength of the binder and gives the finished compound the ability to maintain a very high level of hardness.

End mills are also useful for making a number of cuts such as side milling cuts and profiling, and when extremely precise cuts become necessary, carbide end mills are the way to go, especially when working with difficult materials and when an extremely precisely finished product is necessary for medical, or say, aerospace applications.

While some cutting tools can only cut in one direction or are designed to make plunge cuts, many end mills are designed to cut in multiple directions. This is critically important when it comes to contouring or profiling, or even performing a task as simple as beveling an edge. End mills are some of the most versatile cutting tools in machining, due to their ability to make such a wide number of different cuts and marks on a material.

If you’re looking for End Mills For Sale for your machining applications, then look no further than Online Carbide. Online Carbide’s mission is to get you the carbide end mills and other cutting tools that you need, at the quality you need, at prices you will absolutely love.

All of their end mills for sale, and all of their other carbide tools, are manufactured in the United States of America to bring you the quality to which you have become used in your cutting tools. Every one of their drills and mills must pass stringent quality control measures before being offered. That’s the first thing to note - these are not cheap alternatives to quality, they are the real deal.

Secondly, Online Carbide offers these drills and end mills for sale directly to consumers in order to keep costs down - which means your savings are up. If you were used to buying your carbide cutting tools from a distributor, you were paying a premium, though you might never have been used to it. Online Carbide makes it possible for you to get the same carbide drills and mills for less without ever sacrificing an iota of quality.

Visit their website, OnlineCarbide.com today for more information on their end mills for sale, and don’t be hesitant to reach out to them at 630-238-1424 if you have any questions.

Posted May 6, 2020 00:12

![]() April 16, 2020 03:12

April 16, 2020 03:12

If you are new to the world of machining, you’re probably wondering why there are so many different options in cutting tools, mills and bits. You’re no doubt no stranger to the prevalence of Carbide Cutting Tools, and if so, you’re probably just as familiar with the cost. They can be fairly expensive. That being the case, you might be wondering if there’s a reason that you should use carbide cutting tools in your machining.

To answer this question you need to have an understanding of what carbide is. Carbide is a compound which combines a metal, such as tungsten or cobalt, with carbon to give it a very specific structure. Adding carbon to these metals to form carbides gives a number of benefits over other compounds or the native metals.

Think, for example, how iron is strengthened and can be hardened with the addition of carbon. In this case, we don’t call it carbide but rather steel. Steel can be made much harder and much stronger than native iron with the right levels of carbon and the proper heat treatment. The same can be said for carbides like cobalt carbide.

Carbides have a few strengths over metals such as steel. The first is that carbides can be made much harder than steel and other alternatives. Since mills and bits are used in machining, carbide’s ability to hold an edge is a real bonus when working with metals. Carbide cutting tools can cut more efficiently since they will hold their edges longer, which means that they will last much longer than alternatives. High heat is generated during milling and machining, and carbides are also fairly stable under the stress of high temperatures. Another benefit that carbide cutting tools can offer you is a smoother finer finish.

Even though carbide cutting tools cost a premium over steel, titanium and other alternatives, because they are resistant to wear and temperature, they will last significantly longer under the same circumstances than these alternatives. That justifies the higher up front cost - they are superior materials and will last longer, which will actually save money in the long term.

If you’re looking for carbide cutting tools, then check out OnlineCarbide.com. Their mission is to provide you the highest quality carbide mills and drills at the best possible prices. At Online Carbide, you can find the carbide end mills that you’ve been looking for, but at much lower prices than the competition. How does Online Carbide accomplish this? By selling directly to you instead of through a distribution network. It saves you money and gets you the same quality tools.

Better yet, everything they offer is made right here in the United States of America. You can save even more by getting free shipping through their website on orders over $250 dollars. If you need carbide cutting tools, OnlineCarbide.com is the way to go. Visit their website or contact them via email at sales@onlinecarbide.com or by phone at 630-238-1424 if you have any questions regarding their products.

Posted April 16, 2020 03:12

![]() April 7, 2020 09:14

April 7, 2020 09:14

Spot Drills aren’t something the average consumer is going to enter into their search engine while wasting time in their cubicle. It’s a specialized kind of product with a focused market. If you don’t go online already knowing the subject, chances are you aren’t going to leave the internet with additional knowledge about the subject. No, you’re online searching for something specific and you’ve got two thoughts in mind - who makes the best and what’s it going to cost? Right? Right.

Okay, expert, if you’re here looking for the best Spot Drills available at the lowest prices, then you’ve struck pay dirt. Online Carbide manufactures the finest drills for machinists and machine operators and sells them at factory direct prices and there’s more.

Customers who know about machining tools, know the search is over when they see the prices and other benefits of purchasing from Online Carbide. It’s no secret and hasn’t been a secret for a long time. Unlike many of their competitors, Online Carbide designs, engineers, manufactures and sells their machine tools in the USA. Many competitors re-package offshore products built to inferior standards with brand names meant to sound like the tools are made in America, but they’re not.

Online Carbide insures their Spot Drills perform at the highest levels by utilizing premium carbide material to avoid issues like deflection and to provide additional longevity to the cutting edges of tools. They also add edge-strengthening compounds like Titanium Aluminum Nitride (TiAlN) and a Bright Finish to the Spot Drills or Zirconium Nitride (ZrN) and other finishes for other tools, making them perform better and last longer than many of their competitors.

There’s more to the story. Because Online Carbide sells online at factory direct prices, they know sweetening the deal makes a good deal into a great deal. They accomplish the sweetening by offering free shipping on orders over $250. If you’re in the market for Spot Drills made in the USA, built stronger with better alloys and sold at prices that make even the stingiest accountant sing with delight, then Online Carbide is ready to take your order.

Selling the best made equipment doesn’t mean anything unless you sell them in the right sizes with the right specifications. Online Carbide sells a full range of sizes and configurations of drills. They offer 90° Bright Finish and 90° TiAlN coated Spot Drills. They also have 120° Bright Finish and 120° TiAlN coated models. Each style of Spot Drill comes in diameters from 1/8 inch up to 1/2 inch.

Customers can find whatever size and model of Spot Drill they may need easily at www.onlinecarbide.com. The website is simple to navigate and saves time with its broad selection of products. Customers with questions or with large orders can send an email to sales@onlinecarbide.com or they can call 630-238-1424 between 8am and 5pm Monday through Friday Central Standard Time. Isn’t it time to quit messing around and buy from the experts at Online Carbine? You might discover your career advancing to new heights.

Posted April 7, 2020 09:14

![]() March 4, 2020 06:21

March 4, 2020 06:21

When it comes to end mills, many new users assume that specialized end mills are only for working with harder materials like steel. Soft materials like aluminum pose their own unique challenges and require specialized tools to mill properly. Using the wrong cutting tools while working with aluminum can quickly cause issues, including damage to the workpiece and the cutting tool itself. If you are looking for End Mills For Aluminum, it’s important to choose the correct tools for the job.

When machining aluminum, there are a number of unique material concerns that you will not find when working with other materials. One of the biggest issues is that aluminum forms extremely fine chips when it is being milled. These tiny chips are practically a powder, which means they can be hard for the end mill to eject them from the cutting area.

If your end mill fails to properly eject the fine chips produced by aluminum, they can build up around the base of your end mill. The heat produced by cutting can quickly cause the powdered aluminum to fuse and compact into a mass that can damage your end mill or your workpiece. End mills for aluminum are designed to ensure that any aluminum chips are quickly evacuated from the cutting area.

One way end mill design can help achieve the chip evacuation needed is by lowering the flute count. This gives more space between each flute and, combined with the proper helix angle, makes it easy for chips to fly clear of the end mill. Most aluminum end mills feature no more than 3 flutes, giving the ideal combination between cutting power and chip evacuation.

Another common feature found on end mills designed to cut aluminum is a coating of zirconium nitride. This golden ceramic material is used as a coating for a wide range of tools. ZrN serves a number of functions. It is a very hard coating that protects the surface of tools and extends their working life. ZrN also has a lower coefficient of friction than carbide, making it harder for fine aluminum chips to cling to the cutter while in use. This smoother surface also causes less friction while cutting, which can also increase the performance of your end mills.

Here at Online Carbide, we offer high-quality solid carbide end mills and drill bits. Our carbide end mills for aluminum are made with three flutes and coated in ZrN to ensure maximum performance. You can find our aluminum cutting tools in sizes ranging from ⅛” to ¾”.

So if you shop needs so new end mills for milling aluminum parts, visit our shop today at http://www.OnlineCarbide.com. We offer a wide selection of solid carbide cutting tools including thread mills, drill bits, specialty end mills, and more. If you have any questions about our carbide tools, feel free to reach out to a member of our team by calling 630-238-1424 or sending an email to sales@onlinecarbide.com.

Posted March 4, 2020 06:21

![]() February 21, 2020 06:58

February 21, 2020 06:58

When it comes to milling, having the right end mills for every job is essential. Over time your end mills will start to wear down and need to be replaced. If you need new end mills, Online Carbide is here to help. Whether you need straight or Tapered End Mills, their quality solid carbide options will get the job done at a great price point. Don’t overpay for the cutting tools you need when you can get them from our team at Online Carbide.

Here at Online Carbide, we do not deal with middlemen like most of the industry leaders for milling cutting tools. Instead, we sell our cutting tools directly to their customers so you can save big when you deal with Online Carbide. Unlike a lot of the affordable end mill options, all of the end mills from Online Carbide are made in the USA using the latest robot fed 5 axis CNC grinders and high-quality solid carbide stock.

When it comes to milling cutting cools, you can’t beat the lifespan of solid carbide tools. Metal tools will wear down quickly and they are more likely to oscillate at high speeds, potentially damaging your work. Carbide itself is a type of ceramic that can hold an edge amazingly well, but in its natural state, it is a fine powder. By mixing tungsten carbide with metal, we are able to create a cermet, half ceramic, and half metal. This substance, colloquially known as carbide, is an ideal cutting tool material.

Carbide is not only rigid enough to operate at high speeds, but the ceramic component helps to hold the edge on the tool. This greatly extends the lifespan of the tool when compared to a metal equivalent. We only use the finest carbide stock to make our tools, no carbide coated metal or other cheap knockoffs.

Depending on your needs, we also treat our end mills with several different finishes. Our standard bright finish is simply polished carbide. While this does not add any extra edge retention or insulation, the polishing does make it easier for the chips to be evacuated. Many of our tools feature a titanium aluminum nitride coating also known as TiAlN. This coating helps to extend tool life by keeping end mills cooler. When heated, TiAlN forms a layer of Aluminum Oxide, which insulates the body of the end mill and deflects heat from the cut into the chips instead of the core of the tool. For our end mills for aluminum, we offer a Zirconium Nitride coating, also called ZrN. ZrN helps lower the friction on the end mill to easily evacuate chips and prevent caking of powdered aluminum.

If your shop needs new cutting tools that will perform and last, Online carbide has dozens of amazing options. Whether you need a drill mill or our full form thread tapered end mills, we have the options you need at the manufacturer direct prices you will love. Don’t spend more than you have to just to get the high-performance tools you need. If you need any information about our product line or you would like to request a custom ground mill, you can reach our team by phone at 630-238-1424 or email sales@onlinecarbide.com.

Posted February 21, 2020 06:58

![]() February 3, 2020 04:51

February 3, 2020 04:51

If you regularly machine harder materials, such as steel, you know the horrible chatter that occurs when your cutting tool makes contact. Tools vibrate while in use, which results in chatter. The higher your speeds and feeds, the louder the chatter. One way to significantly decrease chatter is to make your cuts using Variable Flute End Mills. These end mills are specifically designed to prevent oscillation and, consequently, chatter.

Here at Online Carbide, we produce high-performance solid carbide cutting tools. We are proud to offer machinists and shops the highest quality end mills on the market. Each of our cutting tools if made to precise standards using our robot fed 5 axis CNC grinders. Unlike the big-name brands, we do not sell our cutting tools through any big box stores. This helps us cut out the middlemen and offer our products directly to users at manufacturer-direct prices.

When it comes to milling cutters, you need tools that can handle abuse and last. That’s what makes carbide such an ideal material. The ceramic carbide powder is cemented together with strong cobalt metal. The combination of these materials creates a substance with the strength of metal and the incredible hardness and edge retention of a ceramic. This makes these tools incredibly stable even at high speeds.

If you subject a tool to high-speed machining, the cutting edges begin striking the workpiece at regular intervals. This can create an internal resonance which makes the end mill start to vibrate slightly. Basically, because the flutes are evenly spaced, the tool is getting tapped at even internals, increasing the internal resonance. This slight shaking is what causes chatter.

Our variable flute end mills feature a unique design that helps them avoid oscillating at high speeds. The basic idea is that these mills are designed so that every cutting edge is irregularly spaced. In a normal 4 flute end mill, every cutting edge is 90 degrees apart. A variable end mill may feature will feature spacing like 92 degrees, 89 degrees, 91 degrees, and 88 degrees(actual variations will be smaller). These differences mean that every point of contact between a cutting edge and the workpiece will disrupt the natural oscillation within the tool. This can help cut chatter so drastically that many users are shocked at how quiet these tools are when they cut through steel.

Even though these variable mills are quiet, they can still get very hot. In order to keep our variable flute end mills cool while they operate, we treat each of them with a titanium aluminum nitride coating. This TiAlN layer helps protect your end mills by forming a hard layer of aluminum oxide on the surface of the mill once it reaches high temperatures. This aluminum oxide layer is extremely chemically stable while also having a low thermal conductivity. This means that more of the heat will be deflected with the chips instead of heating the end mill.

So if you are sick of loud chatter and worn down end mills, maybe it’s time to try something new. Here at Online Carbide, we have 4 flute degrees in sizes ranging from ?” to ¾”. These mills can help you get the job done without causing a major headache. If you would like to know more about these end mills, or any of our other quality cutting tools, you can reach a member of our team at sale@onlinecarbide.com or by phone between 8 am and 5 pm CST at 630-238-1424.

Posted February 3, 2020 04:51