![]() November 6, 2020 01:02

November 6, 2020 01:02

Drill bits are essential manufacturing tools that are often subjected to a lot of use and abuse. Because these cutting tools regularly have to undergo exposure to high friction forces and the heat that results, bits can wear down quickly. If you are trying to find the right drill bits for your shop, it’s worth taking the time to make sure that you are ordering your tools from a reliable drill bit manufacturer. Working with reliable manufacturers will ensure that your shop will have tools that will get the job done and last longer than other options.

Location

One of the biggest factors when it comes to choosing a drill bit manufacturer is their location. Many machine operators try to save money by buying their tools overseas. Sadly the reduced price tag usually comes with a different kind of cost. Tools manufactured overseas are often of inconsistent quality and can quickly dull or fail unexpectedly. Dealing with American manufacturers helps to ensure that you are buying tools that are made with reliable materials and have undergone proper quality control testing.

Another distinct advantage of ordering tools from American manufacturing companies is the fact that US based businesses share similar hours to US based machining businesses. This means that if you do experience an issue with your tools, you can usually reach a customer service associate when you need them instead of having to leave a message or send an email that might sit unopened for days.

Material

Another huge factor to consider when choosing your tools is their material composition. Hardened steel tools tend to be an affordable option and high speed steel(HSS) drill bits and end mills have become increasingly popular due to their ability to keep their temper even under the temperatures that come with high speed machining. Despite the advantages of HSS alloys, even the finest tool steel is still no match for carbide tool stock.

Carbide tools are made using tungsten carbide tool stock. This material combines ceramic carbide material with cobalt metal as a binding agent. The cobalt metal provides strength while the ceramic material serves as a heat resistant material that helps to keep edges sharp and keeps your bits rigid. This means that carbide drill bits will be more accurate and they will last longer than steel twist bits.

If you are looking for high performance solid carbide drill bits for your shop, you need to check out the options available from Online Carbide. Online Carbide is an American drill bit manufacturer that creates high quality end mills and drill bits from micro-grain tungsten carbide tool stock. Their tools are machined using extremely accurate CNC grinding machines and sold at manufacturer direct prices. This means that your shop can get a great deal on the drill bits that they need. The Online Carbide catalog includes jobber drills, stub drills, spot drills, center drills and a wide variety of end mills. If you have any questions about any of their products, you can send their team an email at sales@onlinecarbide.com.

Posted November 6, 2020 01:02

![]() November 3, 2020 05:19

November 3, 2020 05:19

If you have ever used a tap and die tool to produce threads on pipe or any other workpiece, you know just how frustrating the process can be. These tools are both time consuming to use and capable of jamming. This fault can potentially damage your workpiece and your tools. Luckily you can avoid all of the hassles of dealing with these tools when you thread mill pipe threads using a milling machine.

Computer Numerical Control(CNC) based milling machines have become one of the most important production technologies when it comes to creating custom components through material removal. By utilizing this technology, threaded components can be cut at rates much faster than tap and tie tools. Depending on the specific form of milling cutter being used, you can thread mill pipe threads in a single pass!

Full Form Thread Mills

The fastest way to thread a component is with a full form thread mill. These tools are designed with a row of small cutters that can cut an entire threaded surface quickly and easily. By dropping the length of a thread pitch during a 360 degree pass, every cutter terminates where the one below it began, forming a perfect helical thread. These tools can can a wide variety of thread sizes, though they can only cover a single thread pitch. They are typically available in a number of options to facilitate the cutting of specific tapered threads such as NPT threads. While these tools are definitely the fastest option, but not always the most versatile.

Single Pitch Thread Mills

Single pitch mills are designed to cut an entire threaded surface using only one cutting point. This requires a much longer tool path where the cutter moves allow the entire distance of the threads. While these tools take significantly longer than full form thread mills, they have many more applications. One obvious advantage is the ability for these tools to cut threads with different pitches without having to switch tools. Because the cutting surface on these tools is so much smaller, they can also be used for more delicate tasks. If you are threading a thin walled surface or a component with a delicate overhang, these single pitch tools will be the best option.

If you are looking to thread mill pipe threads or other threaded surfaces using a milling machine, you need to invest in high quality tools. Because the small teeth on these cutting tools are so delicate, solid carbide tools are one of the best options. Tools made from carbide are far more stable than steel tools and they will stay sharp longer, even at high temperatures.

Online Carbide is an American manufacturer of high quality solid carbide end mills and drill bits. When you visit www.onlinecarbide.com, you can find a wide variety of both full form and single pitch thread milling cutters. If you have any questions about any of the tools they carry, or you are interested in ordering custom end mills for your shop, you can reach a member of their team by sending an email to sales@onlinecarbide.com.

Posted November 3, 2020 05:19

![]() November 3, 2020 05:09

November 3, 2020 05:09

Threads are an essential part of many pieces of hardware, allowing them to be secure to surfaces or other components. When creating threads, accuracy is essential to ensure that they can find any other part with complimentary threads. There are several types of threads, and national pipe thread(NPT) has become a standard option for many applications involving pipe fittings. With a carbide thread mill NPT cutter, these specialized threads can be completed in seconds, helping to speed up the production process of machining NPT pipes and compatible components.

NPT threads were created in order for there to be a unified system for how threads were produced to ensure compatibility between pipe fittings. These threads use a tapered design that helps the pipe fittings to remain secure and water tight. There are also special NPTF threads used for fuel applications that are designed to provide a leak free seal without the need for teflon tape and other leak prevention applications.

The traditional techniques for producing these threaded surfaces were manual tap and die cutters. These tools were slow and, due to poor chip breaking, were susceptible to jamming and damaging the component being threaded. More advanced threading machines, like those commonly found near metal pipes in hardware stores, can complete the task of threading easily and with little risk of failure.

As automated milling machines have become a more prominent fixture in manufacturing, specialized end mills have been created to help cut threads with incredible precision and speed using a milling machine. Full form carbide thread mill NPT cutting tools are designed with a series of points along the cutting surface. By dropping the tool by the pitch of the threads, you can allow each point on the cutting to terminate the 360 degree cut where the point below it started cutting, producing a perfect helical thread. These amazing cutting tools can complete an entire threaded surface in one quick 360 degree pass, making them the fastest manner of thread cutting developed.

Each of these full form thread cutters are only designed to cut a single thread pitch, though they can cut a wide range of thread sizes as long as the cut is set up to steadily move the cutter by the length of a thread pitch during the pass. If you need to add threads to a workpiece that is particularly thin walled or less stable, single pitch thread mills can cut a wider range of threads, though they have to trace along the entire length of the thread.

If you are looking for carbide thread mill NPT cutters to help your shop speedup production, you can find them at www.onlinecarbide.com. Online Carbide is an American manufacturer of high quality end mills and drill bits. Their solid carbide thread mills are designed to produce accurate threads quickly so you can cut down on production time without sacrificing quality. If you have any questions about their tools, feel free to reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted November 3, 2020 05:09

![]() October 30, 2020 01:31

October 30, 2020 01:31

All cutting tools will suffer fatigue over time, including drill bits. When it comes to finding the right drill bits for milling machines, especially high speed milling machines, being able to resist corrosive forces is paramount. One way to make sure that your bits can handle any task your shop might need is to buy carbide drills. These tools offer several advantages over their steel counterparts that make them the clearly superior option for manufacturing cutting tools.

Carbide is a remarkable material when it comes to producing tools. While carbide might look metallic, this is only partially the case. The actual carbide in carbide tool stock is tungsten carbide, a ceramic material with some remarkable properties. This material is roughly twice as strong and twice as dense as steel. Sadly carbide cannot do much on its own, as ceramics are susceptible to shattering under strains. In order to produce tool stock, powdered carbide has to be mixed with cobalt metal which serves as a binding material.

The resulting sintered carbide material has many properties that make it ideal for producing tools. One of the biggest advantages of carbide drills is their ability to resist heat and retain the sharpness of their cutting edges. The ability that allows metal to retain a sharp edge is heavily influenced by how the metal is heat tempered. Tempering locks the arrangement of atoms in metal’s atomic structure, but high heat can cause metals to lose their temper and shift into less ideal patterns, softening the metal.

Because carbide’s strength comes from its ceramic content, the issue of the edges softening from becoming too hot. This means that solid carbide drill bits can operate at much higher speeds and be used on herder materials like steel and cast iron without the operator having to worry about damaging their tools or their workpiece.

In addition to being tougher than your average metal tools, carbide bits are also more rigid. When a drill bit spins, it also flexes and oscillates. This is similar to how a piece of string might bow widely if spun between the palms of your hands. The effect is far less pronounced with a drill bit and can barely be observed with the naked eye, but this effect can cause drill bits to miss their mark and deflect off of your workpiece. When you buy carbide drills, you are investing in tools with less oscillation that are capable of drilling holes with significantly more accuracy.

If you are looking for a place to buy carbide drills, you can find some fantastic options at www.onlinecarbide.com. Online Carbide is an American manufacturer of high quality carbide end mills and drill bits. Their inventory of drill bits include spot drills, stub drills, and jobber length bits. All of their tools are available at manufacturer direct prices so you can find the tools that your shop needs at a great price. If you have any questions about their products, feel free to send an email to sales@onlinecarbide.com.

Posted October 30, 2020 01:31

![]() October 19, 2020 09:33

October 19, 2020 09:33

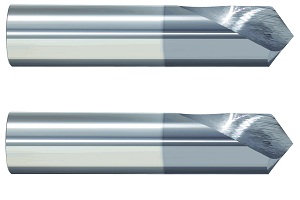

When it comes to milling machines, it is incredibly important to choose the perfect tools for the job. Most end mills and drill bits are designed to perform specific functions. If you want to cut down on tool changes and increase efficiency in your shop, versatile tools like drill mills can help you work faster and smarter.

If you didn’t guess from the name, a drill mill is a milling cutter that combines elements of both end mills and drill bits. The design of the tool’s flutes are similar to a square end mill, making side milling possible. Instead of terminating in a square or ball end like most side milling tools, these tools feature a sharp point like the end of a drill bit. The combination of these design elements make these tools uniquely suited for a wide range of milling operations.

Drilling

Because of the point, these tools are capable of drilling holes. You can use the tip of these tools to spot drill locations for your larger twist bits. They can also be used to drill holes the size of your cutter. If you know that you will need to drill holes and perform any of the other tasks listed below, you can use drill mills to kill several birds with one stone.

Milling

In addition to drilling holes, your drill mills can also perform side milling tasks. Because of the design of their flutes, drill mills can be used to drill a hole into your material and then side mill a slot using that hole as a starting point. They can also be used to side mill V shaped notches using the tip of the cutter. Using just one of these unique cutters can help you avoid the tool changes normally needed to perform all of these tasks.

Finishing

Another great use for these tools is finishing your workpiece. The point of your drill mill is perfect for chamfering or beveling the edges of your workpiece in order to remove any sharp edges. In a similar manner, you can use these tools to deburr a workpiece. The sharp point of these cutters also make them perfect for engraving and other fine finishing tasks.

If you are looking to find some versatile drill mills for your shop, you need to check out www.OnlineCarbide.com. They are an American manufacturer of high quality end mills and drill bits made from tungsten micrograin carbide tool stock. The offer drill mills with a polished carbide finish as well as options that feature a TiAlN/AlTiN coating that can help increase your tool’s ability to resist fatigue from high temperatures. As an added bonus, all of their tools are available at manufacturer direct prices so you can always find a great deal on the milling cutters you need. If you have any questions about their products, feel free to contact a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted October 19, 2020 09:33

![]() October 13, 2020 02:46

October 13, 2020 02:46

Interlocking components have to be machined with threaded surfaces to accommodate the correct bolt sizes. This leaves little room for error and the tools for manufacturing threads have to be extremely precise. For years, tap and die tools were considered to be one of the best options for cutting threads, but these tools are relatively slow and cannot complete a threaded surface in a single pass. Luckily powerful CNC milling machines and solid carbide thread mills are capable of cutting threaded surfaces quickly and accurately.

Thread mills are uniquely designed end mills that are used solely to cut screw threads into a workpiece. The fastest way to produce threads is to use a full form thread mill. These tools have a row of pointed cutting “teeth” along the length of their cutting surface. The spacing between these cutting points are designed to equal the pitch of the final threads. These tools are extremely useful because they can cut an entire threaded surface in a single 360 degree pass. During its rotation, the cutter drops the distance of a thread pitch, so that each cutting point terminates its cut where the point below it began. This creates a perfect helical threaded surface in seconds.

These full form thread mills are quick and easy to use, but they can only cut a single thread pitch size. They can cut many sizes of internal and external threads and they can cut both left hand and right hand threads as long as the pitch has to be the same across the board. These tools also require that workpieces be fairly secure, in order to handle the force of the large cutting surface. When it comes to working on more delicate components or milling different thread pitches with one tool, single pitch or single form end mills are the perfect choice.

Single pitch tools only have one pointed cutter instead of an entire row of “teeth”. This means that the tool has to trace along the entire length of the thread. While this process takes longer than cutting with a full form tool, it does come with its own distinct advantages. Single pitch cutters can mill a range of thread pitches and they are ideal for adding threads to thin or unstable sections of your workpiece.

In order to get the most out of your tools, solid carbide thread mills should be used. Carbide tools are stronger and retain their cutting edges better than steel tools. This makes them the ideal choice for thread milling applications, especially when you consider the delicate design of a thread mill’s cutting points.

If you are looking for some high qualitysolid carbide thread mills for your shop, you can find some incredible options from Online Carbide. As an American manufacturer of carbide end mills and drill bits, Online Carbide is dedicated to creating amazing tools and offering them at manufacturer direct prices. You can see their full catalogue, including thread mills, at www.Onlinecarbide.com.

Posted October 13, 2020 02:46

![]() October 13, 2020 02:30

October 13, 2020 02:30

When machining components, drill bits and end mills are the most important types of cutting tools employed on milling machines. Like all cutting tools, drill bits will be fatigued by long term use and eventually lose their sharp cutting edges. While certain operating practices can help prolong tool life, purchasing tools from a reliable drill bit manufacturer is the best way to find tools that are built to last.

There are several types of drill bits available from various tool manufacturers. These bits can vary wildly in both application and quality. Drill bit design varies based on the material the bit will be used on as well as the specific task that the bit is designed to accomplish. Many bits are designed to perform specific tasks and sometimes multiple bits may be needed to complete a workpiece. Once you know what kinds of bits that your shop needs, there are a few more

One of the most important factors when considering which drill bit manufacturer to purchase tools from is the base material used to manufacture their cutters. Many manufacturers make tools from high speed steel(HSS) alloys that are able to retain their hard cutting edges even when exposed to the high temperatures that come with high speed machining.

Despite the fact that HSS tools can handle higher temperatures than even the finest tool steels, they cannot match solid carbide drills in terms of speed and edge retention. Because carbide is a combination of cobalt metal and tungsten ceramic carbide, the ceramic granules in tool carbide are able to offer superior edge retention because they do not rely on heat treatment to maintain hardness. When metals get too hot, they can change their structure and become soft. Ceramics on the other hand are remarkably stable even at incredible high temperatures. This means that your carbide cobalt drill bits are designed to work harder and last longer than any hardened steel tool.

Many manufacturers also coat their tools to offer an extra level of protection for their tools. Typically coated tools will feature a straight uncoated shank followed by a grey, gold, or near black hard coating on the cutting surface. These coatings are typically intended to offer specific benefits like improved thermal stability in order to prevent heat fatigue. Typical coating materials include titanium aluminum nitride for thermal resistance and zirconium nitride which can offer extra hardness and lower friction resistance.

If your shop is looking for a reliable source of drill bits, you need to check out the incredible options available at www.onlinecarbide.com. Online Carbide is an American end mill and drill bit manufacturer dedicated to making high quality cutters from solid micrograin carbide tool stock. Because they do not work with middle men, you can get all of their amazing tools at manufacturer direct prices! If you have any questions about the products they offer, feel free to reach out to a member of the Online Carbide team by sending and email to sales@onlinecarbide.com.

Posted October 13, 2020 02:30

![]() October 12, 2020 06:48

October 12, 2020 06:48

When it comes to working with a milling machine, there are different rules for every material. Aluminum in particular offers a few unique challenges for milling machine operators. When choosing end mills for aluminum, it is important to make sure that you are using the right cutting tools to avoid damaging your tools and your workpiece.

The biggest issue to contend with when milling aluminum is chip production. Machining aluminum is difficult because it is such a soft and flexible metal. As aluminum is machined away, it can form rather large stringy chips. If these chips are not evacuated from the cutting edges, they can be recut into a fine powder. This fine powder can act as an abrasive, marring the surface of your workpiece, or it can heat to the point of friction welding your tool to your workpiece.

Either way, large chips or fine, there are issues that your tool’s design needs to address in order to ensure proper removal of chips. Evacuating these chips is essential for proper operation. The first way to ensure that the chips can be easily removed is to limit the number of flutes being used to make cuts. The more flutes, the smaller the spacing between cuts. Two and three flute end mills are the best option for getting rid of chips easily. The use of four fluted end mills on aluminum regularly cause build up near the base of the end mills.

In addition to choosing the right number of flutes, it is also important to consider the angle of the flutes. Higher flute angles will impart more vertical force on your chips, forcing them away from the base of your end mill. While many end mills have flute angles around 30 degrees, end mills for aluminum tend to feature high helix angles around 35 to 40 degrees or greater. Ensuring that your tools feature those higher helix angles will ensure proper metal removal rates when machining aluminum alloys.

One more factor to consider when choosing an end mill for machining aluminum is the coating used on the tool’s surface. Different coatings offer different properties and, in the case of aluminum tools, the goal is to reduce the friction on the cutter’s surface. Lower friction translates to smoother chip evacuation, which is why many tools will feature a gold colored coating of zirconium nitride(ZrN). This ceramic coating helps lower the tool’s coefficient of friction and increase performance.

If you are looking for reliable end mills for aluminum, you need to check out the options are Online Carbide. They offer three flute ZrN coated end mills with a 37 degree helix angle. These tools are manufactured from solid carbide, which helps to preserve their cutting edges and extend their tool life. If you have any questions about the tools they offer, feel free to reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted October 12, 2020 06:48

![]() October 12, 2020 02:37

October 12, 2020 02:37

There are many different types of drill bits and drill like tools. Sometimes it can be a real challenge trying to tell them all apart. Two of the most commonly mixed up drills are spot drills and center drills. While these tools may look somewhat similar and seem to be interchangeable for certain applications, they have a few key differences that are important to note.

Spot Drills

Spot drills are short tools with a small pointed cutting surface. As their name suggests, these tools are primarily used to “spot” the location where a twist drill bit will be used. On hard surfaces like steel and other metals, drill bits have a tendency to deflect and “walk” off their mark. This can damage both your workpiece and your drill bit.

The point of a spot drill is to create a small dimple that a longer twist bit can easily fit into. This helps to ensure that your bit will find its mark without issue. The biggest consideration when choosing a spot drill is to ensure that the point angle of your spot drill is greater than the point angle of the longer twist bit being used. This will ensure that the bit contacts the bottom of the spotted divot instead of deflecting off its side.

Center Drills

Center drills are another short tool designed with a small point cutting surface. Unlike spot drills, center drills feature a central extension to their point. This small protrusion serves as a pilot drill while the rest of the cutting surface acts as a countersink to widen that pilot hole. These tools are designed to mark the center point of material so it can be prepared to be lathed.

Some machine operators will use a center drill in place of a spot drill. While these tools are certainly capable of creating a dimple in a workpiece, there are a few important differences in design that make them ill suited for spotting. Center drills typically have a more narrow point angle than spot drills, which makes them particularly ill suited for spotting. If you do spot with a center drill, you run the risk of your drill bit deflecting off of the edge of the divot created in your workpiece.

Both of these tools are important for machinists, but they are definitely not always interchangeable. Using the wrong milling cutter for a specific application can have devastating effects including damage to your workpiece or tools. If you are looking for high quality spot drills or center drills, you can find some amazing solid carbide options at Online Carbide. Their carbide tools are designed to offer the same performance as tools from other US manufacturers. You can visit their website at www.onlinecarbide.com to see a full list of their available drill bits and end mills. If you have any questions about the tools that they offer, you can reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted October 12, 2020 02:37

![]() October 9, 2020 03:28

October 9, 2020 03:28

End mills and drill bits are essential tools for machining custom components, but they can also wear down due to the stress of high speed machining. Using carbide end mills can help to provide a longer tool life, but time and heat will wear down the cutting edges on any tool. If you are looking for tools that will last longer, you need to invest in TiAlN coated end mills.

TiAlN, also known as titanium aluminum nitride, is a compound that is deposited on end mills and other cutting tools to help protect them from the strain of high heat applications. TiAlN is applied to tools using physical vapor deposition. This process vaporizes the coating substance and redeposits it on the tool’s surface. The result is a coating of TiAlN that is only 1 to 7 microns thick and perfectly bonded to the cutting surface.

Under normal conditions, high speed machining causes a lot of heat to build up on a tool’s cutting edges. TiAlN helps to increase the thermal stability of end mills by deflecting some of that heat away from the cutting edges. When exposed to high heat and air, TiAlN creates a thin aluminum oxide layer that helps to insulate the end mill. Not only does this help to protect the cutting edges of end mills, but it also helps to deflect heat away and into the chips. This makes these tools ideals for high speed machining.

In addition to protecting the end mill from heat, TiAlN is also a remarkably hard substance. Adding a thin coating of this material to the cutting surface of an end mill is a great way to provide some extra structural integrity to your tools. This will help to keep your edges sharper for longer.

Another interesting trait of this material is the fact that the longer you use your TiAlN coated end mills, the stronger their protective coating becomes. This is an effect known as age hardening. Despite its name, the age hardening process is impacted by how many heat cycles the tools undergo, not the time since they were first coated. As the tools are heated, the TiAlN coating breaks down in AlN and TiN, arranging itself in a manner that helps to increase its structural stability. This helps your cutting tools stay sharper for even longer periods of time.

If you are looking for TiAlN coated end mills for your shop, you need to take a look at the tools offered by Online Carbide. They offer a wide range of drill bits and end mills constructed from high quality carbide tool stock and many of their tools are available with a TiAlN coating. With an inventory that includes end mills, thread mills, drill mills, center drills, drill bits, and more, you are sure to find whatever your shop needs when you visit www.OnlineCarbide.com. If you have any questions about the tools they offer, feel free to contact a member of their team by sending an email to sales@onlinecarbide.com.

Posted October 9, 2020 03:28

![]() October 9, 2020 03:16

October 9, 2020 03:16

When it comes to machining with drill bits, the number of options can sometimes be a little overwhelming. If you have to deal with the confusion of knowing when to use each type of drill, we are here to help. Knowing the difference between a jobber drill and a stub drill or a spot drill and a center drill can make a huge difference when it comes to how they will perform.

Jobber Drills

The most common drill bit is the jobber drill. This is what most people imagine when you bring up the phrase drill bit. These twist bits are most commonly used on softer materials such as wood, but they can also be used on harder materials when deep holes have to be drilled. The biggest issue with the use of jobber length bits is the fact that they can “walk” off target. This is a result of their length and the fact that high speed machining causes tools to oscillate drift off of their mark.

Stub Drills

In order to deal with the issue of drill bits walking off their mark, the stub drill was developed. These shorter drill bits are shorter than jobber drills, but they feature a similar twisted flute design. The shorter length makes them a far more stable option for drilling shallow holes in your workpieces.

Spot Drills

Another way to combat drill bits walking off their mark is to spot your drilling positions ahead of time. Spot drills are extremely short and their cutting surface is limited to their point. Instead of being used to create holes in a workpiece, spot drills are designed to create a small dimple to mark the location where a hole will be drilled. This small dimple makes it easier for longer drill bits to find their mark, so long as the angle of the spot drill’s point is equal to or greater than the angle of the twist bit’s point.

Center Drills

Often confused with spot drills, center drills are actually designed to mark the center point for a lathe. Some operators will try to use center drills to spot locations for drilling with a twist bit, but the point angle on a center drill is usually smaller than the point angle of a twist bit. This difference in angle can lead to drill bits deflecting away from the center drilled position due to the tip not seating properly.

If you are looking for high quality drill bits for your shop, Online Carbide offers plenty of high quality solid carbide drill bits. Their tools are manufactured from high quality tool carbide stock and they offer their tools at amazing manufacturer direct prices. Their catalogue includes jobber drills, stub drills, spots drills, center drills and a wide range of end mills. If you have any questions about the products they carry, feel free to reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted October 9, 2020 03:16

![]() October 8, 2020 08:11

October 8, 2020 08:11

Chamfer mills are small little tools that offer a lot of utility. When people normally imagine end mills, they picture the large fluted side milling tools that are used to remove large amounts of material from a workpiece. Machining tends to require several steps using a variety of distinct tools, including several finishing steps. For many projects, especially those with hard metal edges, chamfering is a necessary step in the machining process. These little milling cutters can complete a wide variety of finishing tasks. The more job one tool performs, the few changes are needed and the faster a workpiece can be completed.

Chamfering

The most obvious use for a chamfer mill is to chamfer. Chamfering is the process of breaking an edge where two flat planes meet to create a third plane. This process is useful for a number of reasons and it can help to ensure that pieces have a fine finish without too many sharp edges. The angle of a chamfer is determined by the tool being used or the ability for the milling machine to work at an angle.

Beveling

Often confused with chamfering, the process of beveling completely alters one of the planes where two sides of a workpiece meet. For thin areas, some chamfer mills can bevel in edge in a single pass. They can also be used to bevel larger surfaces when you are finishing a workpiece, though it may take multiple passes to complete a bevel that is larger than the size of the cutting tool’s point.

Spotting

Another important job that a chamfer mill can accomplish is spotting. Spotting helps to mark the location for holes in your workpiece by cutting a small dimple into your workpiece. This process helps to ensure accurate hole placement and it avoids the risk of having your drill bit walking off its mark. Because chamfer tools are much shorter than drill bits, they offer a more stable point to begin drilling a hole. They can also be used during the finishing process to countersink holes smaller than the diameter of the cutting point’s diameter.

Deburring

Machine milling is a precise process, but it is not always a clean one. Small metal burrs are often lifting but not fully removed by cutting tools, creating a series of small raised points along otherwise smooth surfaces. A chamfer mill can trace a piece’s edges in order to quickly remove any small burrs and even add a small chamfer if desired. This will help ensure that the final product has smooth and accurate edges.

With so many uses, chamfer mills are an essential tool for any machinist’s shop. If you are looking for high quality solid carbide chamfer mills, you need to check out the options available at Online Carbide. They offer chamfer mills along with a wide selection of other sturdy solid carbide tools. You can find all of their tools at manufacturer direct pricing when you visit their website at www.onlinecarbide.com.

Posted October 8, 2020 08:11

![]() October 8, 2020 07:50

October 8, 2020 07:50

Machining custom components with a milling machine is an amazingly precise yet time consuming process. One way to cut down on the operating time it takes to mill components is to limit the number of tool changes that are required. Drill mills are one of the most versatile milling tools out there and their unique design makes it easy for them to perform a list of tasks that would normally require several types of specialized end mills. Finding reliable drill mills for sale is a great way to speed up your production process.

Just like its name suggests, a drill mill is a tool that combines elements of both traditional side cutting end mills and axial cutting drill bits. The flutes of these tools are designed with the same profile as end mills, which makes them capable of performing side milling operations. What makes these tools truly unique is their sharp points, which are very different from the traditional square and ball ended designs employed by most end mills.

Because of their flute construction, these tools can be used to perform simple cuts. Because of the pointed tip, several passes would be necessary to cut out large areas. Their point does make these cutters unique suited to machining v shaped notches in your workpieces. Their points also make it possible for drill mills to perform some drilling operations, a task that end mills are not well suited for. The point of a drill mill can easily drill small holes or be used to spot drill to mark the location for deeper holes to be drilled. The pointed tip can also be used in place of a chamfer mill for applications like chamfering, beveling, and deburring your workpieces.

If you are looking to get the most out of your drill mills, you need to consider their construction. The best cutting tools will be constructed from solid carbide tool stock. Carbide is more rigid than steel and much more resistant to fatigue, meaning carbide tools can run faster and last longer than their counterparts. These end mills are even more resistant to high temperatures than high speed steel alloys. In order to give these tools some extra heat resistance, many manufacturers coat their tools in a layer of titanium aluminum nitride. This dark grey coating helps to provide extra heat resistance by forming an insulating layer of aluminum oxide at high temperatures.

If your shop is searching for some high quality drill mills for sale, you need to check out Online Carbide. They are an American manufacturer of high quality cutting tools machined from micro-grain tungsten carbide tool stock. Their inventory includes end mills, drill bits, and drill mills for sale at amazing manufacturer direct prices. You can see all of their amazing products at www.onlinecarbide.com. If you have any questions about their tools, feel free to reach out to a member of their team by sending an email to sales@onlinecarbide.com.

Posted October 8, 2020 07:50

![]() October 2, 2020 06:20

October 2, 2020 06:20

When it comes to cutting tools like drill bits, solid carbide drills will always offer superior performance compared to other tool materials. If you are looking for the best possible tools for your machining shop, choosing products from reliable carbide drill manufacturers will ensure that you are purchasing tools that are designed for long term performance.

Drill bits are extremely versatile tools. Many machining applications require the drilling of holes, though the process is not always as straightforward as just drilling a hole. Precision matters, especially when it comes to the production of custom components. Drill bits are notorious for the fact that they are not always the most accurate tools. Their length, combined with the high speeds that they operate at, make it very easy for these tools to oscillate, deflect against a hard surface, and “walk” off their mark. All of these issues can potentially damage your final workpiece.

Tools from carbide drill manufacturers can help your shop combat these drill bit based issues. Carbide is far more rigid in steel, making it ideal for drill bit manufacturing. Even longer carbide bits will oscillate far less than their steel counterparts, helping to provide accuracy when machining. Shorter carbide stub drills offer incredible accuracy and tiny spot drills are designed to help create small dimples in order to mark the location where deeper holes will be drilled on a workpiece. This helps to offer a solid footing for when longer twist bits are used.

The reason that carbide is so perfectly suited as a tool material is the fact that it is a composite material made by combining a binding metal and ceramic powder. The actual “carbide” part of these tools is tungsten carbide, a powdered ceramic material composed of tungsten and carbon. Small granules of this ceramic material are introduced to cobalt metal just like adding aggregate to concrete. The resulting material has the resilience and flexibility of metal along with the density and resilience of ceramic.

Carbide tools can also run faster than conventional metal cutters. Even high speed steel alloys can’t match carbide in terms of heat resistance. This is because of the fact that the cutting edge of these tools is strengthened by ceramic carbide, a material that does not soften at the high temperatures caused by milling operations. When combined with specialized coatings like titanium aluminum nitride(TiAlN), carbide tools will stay sharper and last even longer than polished carbide tools.

If your shop needs strong and accurate drill bits, you need to look into ordering from a trusted carbide drill manufacturer. Online Carbide is an American tool manufacturer specializing in high performance drill bits and end mills. Their list of products includes center drills, spot drills, stub drills, jobber drills, and more. All of their products are offered at manufacturer direct pricing so you can save on quality tools for your shop. To see their full catalogue, visit www.onlinecarbide.com.

Posted October 2, 2020 06:20

![]() September 14, 2020 04:14

September 14, 2020 04:14

When it comes to machining custom components, time is usually the enemy. There are many ways to increase your production speed, but variable flute end mills are one of the best all around solutions for jobs where increased speeds and feeds produce a lot of tool chatter. These tools are specially designed to cut down on chatter so you can operate at high speeds without risking our tools or your workpiece.

Chatter

Tool chatter is a common and irritating side effect of high speed machining. When tools spin rapidly, they will naturally begin to oscillate. While these oscillations are virtually impossible for our eyes to perceive, if you watched an end mill in slow motion you would see them shake and flex back and forth at high speeds. This causes small impacts as the cutter bumps into the workpiece along its path, producing a loud screeching sound. This effect is especially prevalent in tools constructed from high speed steel alloys, but it can even occur in more rigid carbide tools.

Conventional Tools

Most tools are designed to be perfectly symmetrical. Imagine a four flute end mill and you will obviously picture the cutting edges being spaced at perfect 90 degree variables. At consistent speeds, the timing between each cutting edge hitting the workpiece becomes perfectly even. This regular impact of the tool against the workpiece helps to feed into the tool’s oscillations, like applying even forces to a pendulum in order to keep it swinging regularly.

Variable End Mills

Rather than being designed with perfect symmetry, variable end mills are slightly asymmetrical. This might seem rather counterintuitive when it comes to tool design, as the even distribution of cutting forces helps to maintain your cutter’s structural integrity. Despite this fact, small changes can go a long way when it comes to changing how tools perform.

The spacing of variable flute end mills are just different enough to change the timing between strikes without significantly affecting the internal strain on your cutters. This means that these tools will help to dampen their own internal harmonic vibrations so they can operate at high speeds without oscillating back and forth dramatically. This unique design makes it possible to run your tools faster without having to deal with loud tool chatter.

If you are looking to improve your shop’s production times, variable flute end mills could be the perfect solution. With these specialized end mills, you can work faster without increasing the risk to your milling machine or your workpiece. You can find high quality variable end mills when you visit www.onlinecarbide.com. They are an American manufacturer of high quality end mills and drill bits constructed from solid micrograin tungsten carbide. Their variable end mills are all coated in a layer of titanium aluminum nitride(TiAlN) to help protect them from the heat of high speed machining. If you have any questions about the tools they offer, you can reach out to the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted September 14, 2020 04:14

![]() September 14, 2020 03:33

September 14, 2020 03:33

Aluminum, despite being much softer than steel, presents its own issues when it comes to milling. Milled aluminum is a common material used to construct parts that need to be light but strong. In order to properly machine this metal, the right end mills for aluminum have to be used. Trying to mill components using the same tools you would use for harder metals like steel would be a mistake that could ruin both your tools and your workpiece.

Chip Size

The largest hurdle to overcome when machining aluminum is chip size. Steel is strong and when you cut into it at high speeds, shavings are removed almost like you’re working with wood. Aluminum forms much finer chips that are almost a fine powder. These chips, if not properly evacuated from the cutting area, can build up around the base of the cutter and compact to the point where it can seriously damage your cutter.

Flute Count

When choosing end mills for aluminum, you are going to want to limit the number of flutes on the cutter. Fewer flutes means more space between flutes and more distance between cuts. This gives the fine chips from each cut more room to be successfully evacuated from the toolpath. Most aluminum specific milling cutters have three flutes, though two and four fluted options are occasionally used.

Flute Angle

So the number of flutes is crucial, but the angle of those flutes is also important. Flute angle influences the ability for the chips to be accelerated away from the cutting path. The higher the flute angle, the faster the chip evacuation. Most end mills use a lower helix angle around 30 degrees, but end mills for aluminum should have helix angles ranging from 35 to 45 degrees.

Coating

Finally you are going to want to take a look at the coating being used on your end mills. These coatings not only help to protect the tool from heat and strain, but coatings like the gold colored zirconium nitride help to lower the friction coefficient of your end mill’s surface. This means that the coating makes it harder for chips to stick to your cutter and the surface will help those chips slide away smoothly. This material is actually a fine layer of hard ceramic that is deposited onto the surface of the end mill as a vapor, creating a coating that is remarkably strong and thin.

If you want to see some fantastic end mills for aluminum, you need to check out Online Carbide. They are an American manufacturer dedicated to producing high quality end mills precision milled from solid carbide stock. Their Aluminum end mills feature a three flute design with a 37 degree helix angle to promote efficient chip evacuation. If you have any questions about their tools, feel free to reach out to a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted September 14, 2020 03:33

![]() September 14, 2020 03:25

September 14, 2020 03:25

When it comes to choosing tools for your milling machine, carbide is clearly the best option available. Not only are these tools going to allow you to machine harder materials at higher speeds, but they also outlast cutters made from steel alloys. Taking the time to find tools from a reliable solid carbide end mills manufacturer will help ensure that your shop gets the best value when ordering new cutters.

Why Carbide?

Carbide is practically a miracle material when it comes to the production of cutting tools. While tool carbide might look like a metallic alloy, it is actually a finely powdered carbide ceramic(tungsten carbide) mixed into a metal binding material(cobalt). The resulting composite material has the strength of the cobalt to prevent it from shattering, while the dense carbide ceramic helps to keep the tool rigid and the cutting edges sharp.

All metallic tools have to be properly tempered during manufacturing. The tempering process involves heating and cooling the metal in a way that helps to properly harden the cutter so the edges will stay sharp for longer. When heated beyond a certain point, these tools can lose their temper and their edges can soften, leading to premature tool failure.

Because the sharpness of carbide tools is a result of their ceramic content, the temper of the metal does not have a significant impact on the integrity of their cutting edges. This means that they can operate at high speeds that would overheat steel tools. Carbide cutters will even outperform high speed steel alloys.

Finding A Manufacturer

When it comes to ordering carbide cutting tools, the source of your tools matters. A lot of shops try to save money by purchasing cheap end mills from overseas manufacturers. While these tools might be less expensive, that low cost comes with a lower material quality and practically non existent customer service.

Ordering your tools from an American solid carbide end mills manufacturer means that you will be able to trust the material quality of your tools. Just like different alloys with metallic tools, there are various grades of carbides and overseas manufacturers tend to cut cost by using lower quality carbide stock. Dealing with a domestic manufacturer also means that, in the event of difficulty with your cutters, there will actually be a team that can hop on a call and assist you when you need help.

One reliable solid carbide end mills manufacturer is Online Carbide. They make all of their end mills and drill bits from high quality micro grain tungsten carbide. By using computer guided 5 axis CNC grinders, they are able to produce extremely precise tools for their customers. They carry stand end mills, thread mills, drill mills, spot drills, and other tools. All of their tools are available at manufacturer direct prices so you can get a great deal of the tools that your shop needs. If you have any questions about their tools, feel free to reach out to a member of their team by sending an email to sales@onlinecarbide.com.

Posted September 14, 2020 03:25

![]() September 14, 2020 02:43

September 14, 2020 02:43

When producing interlocking components, the ability to add threads to your workpieces is essential. The production of threaded components has come a long way with the popularity of computer controlled milling systems. Thread milling with solid carbide end mills is one of the fastest and most accurate ways to create clean threads without having to worry about damaging your workpiece.

For decades, most threaded components have been completed using tap and die tools. These thread cutters are still used in some situations, but they come with their own issues. Not only is the use of tap and die tools time consuming, but tool failure can have devastating results. The breaking and proper removal of chips cause these tools to experience jams and breaks more frequently than other methods of thread production.

Instead of having to slowly work specialized tools to cut threads, specialized end mills can get the job done in seconds. There are several different varieties of tools for thread milling, with each serve their own unique purpose. Full form thread mills are the best option for fast base production, as they can complete an entire threaded surface in one 360 motion.

For more delicate thread work, single pitch thread mills are a great option. These smaller tools have a single cutting point. This means that the tool has to travel along the entire length of the threads grooves. This will increase manufacturing time, but makes it easier to thread surfaces with thin walls or delicate surfaces/overhangs. You can also use these mills for mixed production when several different thread sizes have to be cut.

When it comes to the manufacturing of your end mills, thread milling with solid carbide tools will produce the best results. Carbide cutters are harder, less flexible, and more dense than steel tools. All of these qualities make them better suited for thread milling, a process that requires extreme precision. Their rigid structure helps to prevent the tools for oscillating or drifting too far off of their cutting path, which helps ensure smooth milling.

Because carbide is a composite material made by combining metal and ceramic powder, the edges of the tools don’t suffer the same fatigue during machining. The edges on metal tools can wear down, but the ceramic edges of carbide tools resist heat and last significantly longer than tools made with high speed steel alloys.

If you are looking to start thread milling with solid carbide tools, you need to find a quality manufacturer of carbide cutters. Online Carbide is an American carbide tool manufacturer with a wide range of thread milling options. Their thread mills are made from high quality micro grain tungsten carbide tool stock and are coating with a TiAlN coating that helps provide an extra layer of protection against heat and wear. If you have any questions about their tools, feel free to reach out to a member of the Online Carbide team by calling 630.238.1424 or sending an email to sales@onlinecarbide.com.

Posted September 14, 2020 02:43

![]() September 14, 2020 02:33

September 14, 2020 02:33

When it comes to creating custom components out of wood, plastic, or metal, milling machines are one of the most useful fabrication tools. CNC milling uses computer numerical control to guide a cutter along a set path to create incredibly accurate pieces. The actual cutting is performed by specialized cutting tools known as end mills, and the quality of your cutters can make a huge difference. If you are looking for quality end mills for sale, there are a few variables to consider.

Construction

One of the biggest factors when looking for new end mills is their construction. The shape of the end mill and the spacing of its cutting edges will have the most impact on how it performs. Most cutting mills will have square or ball ends, but specialized end mills come in all shapes and sizes.

You also need to consider the materials you will be machining. End mills for aluminum require special flute spacing and flute angles. Harder materials like steel and cast iron will require more flutes than softer materials like wood. If you are looking for a general all around end mill, four flutes tends to be one of the more flexible options.

Material

Next thing to consider is the material that your tools are made from. One of the most common materials for the construction of end mills is stainless steel. Most tool steel for the construction of end mills is made with special high speed steel alloys that can resist extreme temperatures. Regular stainless steel will quickly lose it’s temper and begin to soften when exposed to the heat of high speed machining.

If you are going to be machining steel components or operating at higher speeds and feeds, investing in solid carbide tools might be the best course of action. Carbide combines the strength of metal with the heat resistance, sharpness, and rigidity of tungsten carbide ceramic. These tools will retain the strength of their cutting edges even after continued exposure to temperatures beyond what high speed steel can handle.

Source

The final factor to consider when searching for end mills for sale is the source that you are buying from. It’s pretty common to find solid carbide end mills at low prices from overseas. While these tools tend to be more affordable, they come with their own drawbacks. Material quality is often lacking, leading to unexpected tool failure that can damage workpieces. The long shipping times and time differences with overseas manufacturers leads to a lack of customer service in the event of faulty products.

American tool manufacturers are one of the best sources when looking for high quality solid carbide end mills for sale. Online Carbide is one manufacturer that offers a wide range of solid carbide end mills and drill bits at amazing manufacturer direct prices. If you want to know more about any of their products, feel free to contact a member of the Online Carbide team by sending an email to sales@onlinecarbide.com.

Posted September 14, 2020 02:33

![]() September 9, 2020 02:53

September 9, 2020 02:53

If you work with CNC machines, you know how fast you can wear down an end mill. Cutting tools will not stay sharp forever, especially when they operate at high speeds. If your shop is trying to limit the number of tools you are going through, you need a source of quality carbide end mills for sale. Using solid carbide tools is a great way to work faster and have your cutters last longer.

Carbide is one of the best tool making materials available. By combining the harness and density of ceramic carbide with the flexibility and strength of cobalt metal, carbide tools gain the benefit of being stable at high temperatures with cutting edges that will stay sharp. Carbide end mills can cut through harder materials like stainless steels and cast iron with relative ease. Other end mill materials like high speed steel alloys can perform similar tasks, but typically will not operate at high speeds for nearly as long as carbide tools.

When it comes to finding quality carbide end mills for sale, there are a lot of factors to consider. A lot of shop owners purchase cheap carbide cutters from overseas. While the prices are definitely going to be better with these tools, the unknown level of quality, long shipping times and poor customer service can all lead to their own headaches. Oftentimes you are left working with unreliable tools that manufacturers will not replace in the event of unexpected tool failure.

Working with American end mill and drill bit manufacturers ensures that your business is only purchasing tools constructed from high quality materials. You also have to consider accountability. When you work with American manufacturers, those are businesses you can actually reach during work hours when you need them. You can usually save big on tools when you order directly from manufacturers instead of having to deal with middlemen.

Online Carbide is one independent American manufacturer that has high quality end mills for sale. They machine their tools using high quality tool carbide stock using the same robot fed 5 axis CNC grinders as other leaders in the industry. Their catalogue includes standard square and ball nose end mill cutters, thread mills, drill mills, and a variety of carbide drill bits. All of their tools are designed to offer a long tool life so you can get more work done without worrying about unexpected failure from cheap tools. Many of their tools as TiAlN coated to offer extra strength and heat resistance for high speed machining.

Check out www.onlinecarbide.com to see their entire catalogue. If you don’t see the end mills for sale that your shop needs or you have a special request, you can always reach out to their team by calling 630.238.1424 or sending an email to sales@onlinecarbide.com. They are always happy to help their customers get the tools they need at the best price possible.

Posted September 9, 2020 02:53